Fernüberwachungslösung für Luftkompressoren

Equipped with powerful edge computing capabilities, support for industrial protocols, and IoT cloud compatibility, the IG502 IoT edge gateway offers a reliable solution for remote monitoring of air compressors. Moreover, its sturdy industrial design ensures consistent performance in challenging environments.

Hintergrund

Air compressors, as large-scale mechanical equipment, often require extensive maintenance and troubleshooting over time. However, high power consumption and costly repairs increase the impact of failures, causing significant losses due to delayed fixes and prolonged downtime.

To tackle these challenges, a leading air compressor manufacturer focuses on improving product quality and user experience through innovative technologies. By leveraging network connectivity, they enable maintenance teams to remotely monitor air compressor operations, detect issues early, and address problems proactively. As a result, this approach reduces downtime, lowers maintenance costs, enhances customer service, and adds value to their solutions.

Kundenanforderungen

Überwachung und Fernsteuerung in Echtzeit

Enable real-time monitoring of key air compressor parameters, including temperature, pressure, and speed, using multiple industrial protocols. Additionally, provide remote control to adjust parameters and improve the production process efficiently.

Fehlerdiagnose und vorbeugende Wartung

Use an intelligent system to analyze collected data, diagnose potential faults, and send timely alerts. This helps prevent production delays and protects equipment from damage, ensuring smooth operations.

Datenanalyse und Berichte

Support advanced data analysis to process and visualize operating data. Generate detailed reports and charts to help clients track production efficiency, quality metrics, and equipment utilization, driving continuous improvement and better decision-making.

Lösung

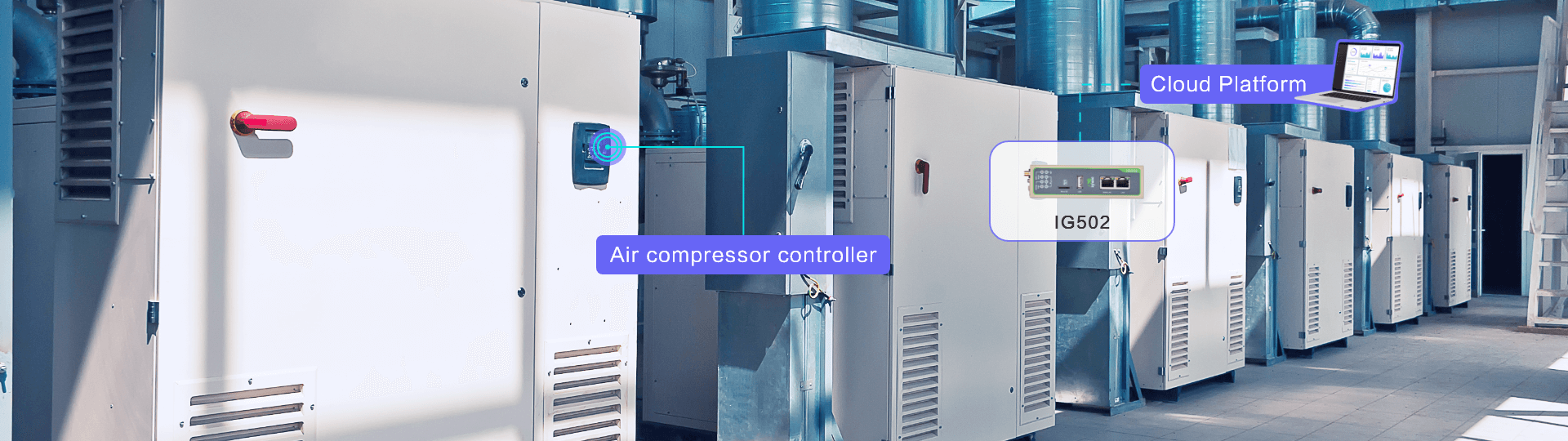

The system includes an air compressor, the IG502 IoT edge gateway, and a remote management platform. The IG502 connects to the air compressor controller to collect key data, such as oil temperature and lubricating fluid levels, in real time. It then transmits this data through the 4G network to the remote management platform, where it is analyzed and processed. Customers can easily view, track, and analyze data anytime on a computer or mobile device.

Additionally, maintenance teams can use the platform to establish maintenance channels with the on-site air compressor. By logging into the client software, they can perform remote monitoring and maintenance. With timely preventive maintenance, potential issues are identified and resolved early, reducing downtime and extending equipment lifespan.

Vorteile

Supports Major Protocols and IoT Clouds for Seamless Monitoring

The IG502 IoT edge gateway works with Modbus TCP/RTU, EtherNet/IP, ISO on TCP, OPC UA Client, and other key industrial protocols. It simplifies sending device data to the cloud for remote monitoring and predictive maintenance, lowering operational costs and improving customer satisfaction.

Python Programmable for Custom Solutions

With an embedded development platform supporting Python, the IG502 IoT gateway allows developers to implement specific business logic and create personalized services easily.

Effortless Management for Large-Scale Deployment

The IG502 gateway offers web interface configuration for quick setup. Using Device Manager, users can centralize device management, monitor gateway status in real-time, and scale deployments efficiently.

Reliable Network Keeps Devices Always Online

The IG502 ensures stable connectivity, perfect for unmanned IoT sites. Key features include:

- Dual SIM with automatic switching to the best network carrier.

- Multi-level link detection for monitoring, redialing, and fault recovery.

- Embedded watchdog technology for uninterrupted operation.

Powerful Edge Computing for Smart Data Processing

Equipped with an ARM Cortex-A8 processor running at 600MHz, with 512MB RAM and 8GB eMMC storage, the IG502 delivers robust edge computing. It processes data intelligently, optimizes performance, ensures real-time responses, and supports smart analytics for on-site devices.