Fernüberwachungslösung für die digitale Fabrik

Digital factories thrive on real-time visualization, predictive maintenance, and data-driven decision-making for efficient operations. InHand’s solutions, featuring high-speed connectivity, industrial protocol compatibility, and Docker support, enable seamless deployment and streamlined management.

Hintergrund

In today’s fast-changing industrial landscape, the need for improved production efficiency, cost reduction, and intelligent operational management is critical. IoT-based solutions for remote management of digital factories have become essential, offering enterprises innovative ways to streamline operations and stay competitive.

Kundenanforderungen

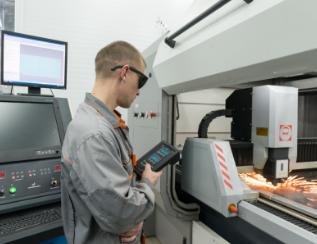

Echtzeit-Visualisierung und Fernverwaltung

Enable real-time monitoring and remote management of factory equipment and automated production lines. Access equipment status, production metrics, and key performance indicators anytime, anywhere for timely decision-making and operational adjustments.

Störungswarnung und vorausschauende Wartung

Deliver fault warning capabilities to identify malfunctions, anomalies, and potential issues early. Implement predictive and preventive maintenance measures to minimize downtime, lower repair costs, and improve equipment reliability and productivity.

Datengestützte Entscheidungsfindung und Optimierung

Record and analyze operational data from factory equipment. Provide data querying and export features to support informed decisions, optimize resource utilization, and enhance intelligent management of digital factories.

Lösung

InHand’s remote monitoring solution for digital factories supports seamless IoT transformation, cost-effective maintenance, and enhanced productivity.

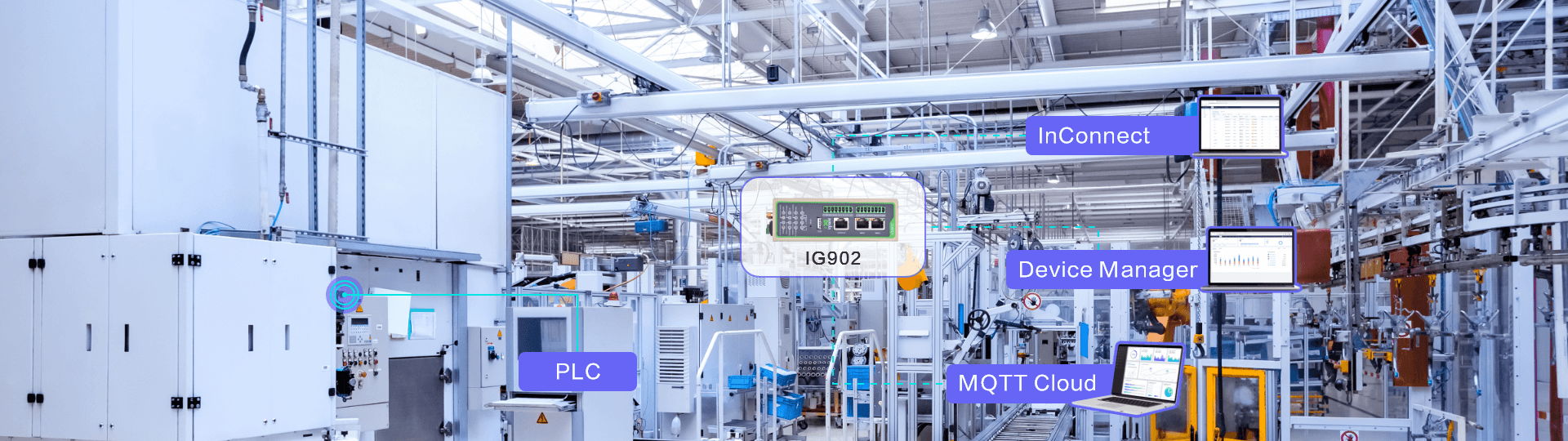

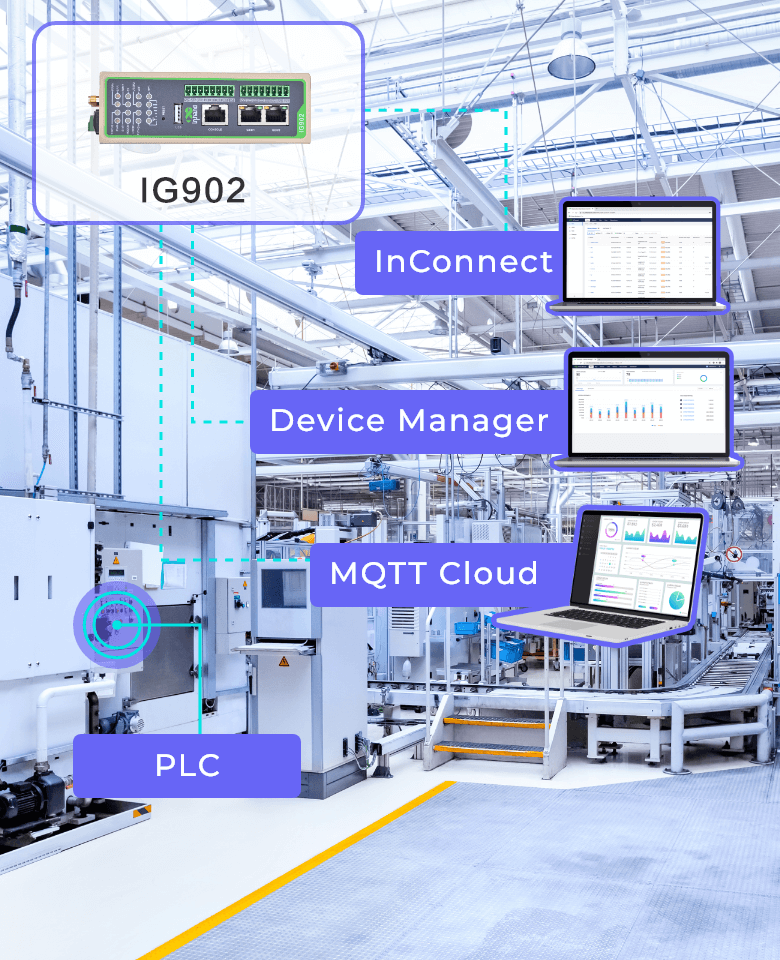

The solution includes field PLCs, the IG902 edge computing gateway, and an IoT cloud platform. The IG902 gateway collects real-time data from PLCs, filters it, and securely transmits it over 4G networks using proprietary protocols to the remote management platform for analysis.

With the InConnect remote access service, maintenance staff can configure, debug, and upgrade onsite PLCs remotely. The DeviceManager platform enables unified device management, remote maintenance, and real-time monitoring, optimizing operational efficiency and extending the lifespan of factory equipment with predictive maintenance.

Kapazitäten

High-Speed, Secure and Reliable Connectivity for Continuous Operation

With LTE, Wi-Fi, and wired options, plus link redundancy technologies, the IG902 IoT edge gateway ensures uninterrupted network transmission, keeping devices online.

Seamless Integration with Industrial Protocols and Clouds

The IG902 edge gateway supports Modbus TCP/RTU, EtherNet/IP, ISO on TCP, OPC UA, and more, enabling easy data transmission to the cloud for remote monitoring and preventive maintenance, thus reducing operational costs.

Python Programmable for Customization

Featuring an embedded development platform supporting Python, the IG902 industrial IoT gateway allows developers to implement specific business logic and tailored solutions.

Efficient Development with Docker

Docker support enables flexible, scalable application deployment, reducing resource consumption and simplifying environment configuration.

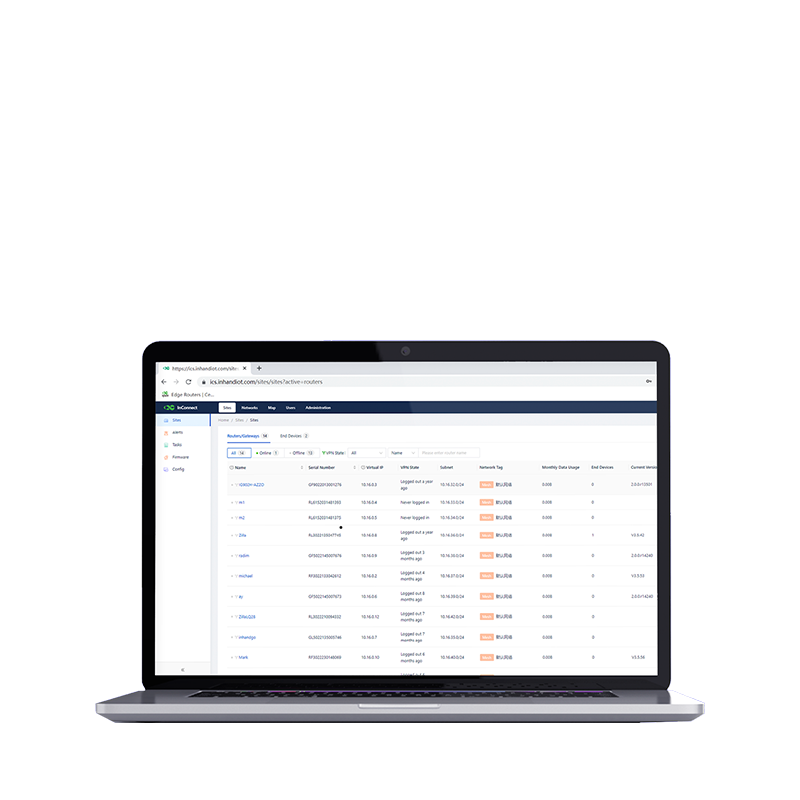

Remote Maintenance with InConnect

The InConnect remote access service provides secure VPN tunnels for remote PLC debugging, updates, and parameter adjustments, ensuring swift responses to equipment issues.

Streamlined Management for Large-Scale Deployments

The IG902 edge gateway supports web interface configuration for quick setup, and Device Manager centralizes device management, enabling real-time gateway monitoring anytime, anywhere.