Energieeinsparung und Emissionsreduzierung für Fabrik-HLK

Durch die Nutzung von Echtzeitüberwachung, automatisierten Energiesparstrategien und Datenanalyse verbessert die xEnergy-Lösung die Effizienz des HLK-Managements in Fabriken und hilft Fabriken, Energieziele zu erreichen und Abfall zu reduzieren.

Hintergrund

Eine Fabrik verfügt über mehr als 300 Klimaanlagen in Produktionsbereichen und Büros, was zu einem hohen Stromverbrauch führt. Aufgrund mangelnder Kontrolle laufen Klimaanlagen oft in unbesetzten Bereichen, haben während des Betriebs geöffnete Fenster oder bleiben nach Feierabend eingeschaltet, was zu erheblicher Energieverschwendung führt. Das Management möchte diese Verschwendung reduzieren und Energieziele für die einzelnen Abteilungen festlegen, verfügt jedoch nicht über die erforderlichen Daten.

Um die Energieverschwendung durch die Klimaanlage zu reduzieren, möchte der Kunde intelligente Sparmaßnahmen implementieren und den Verbrauch nach Abteilungen überwachen, um Benchmarks festzulegen und Energiesparziele zuzuweisen.

Kundenanforderungen

Umweltüberwachung

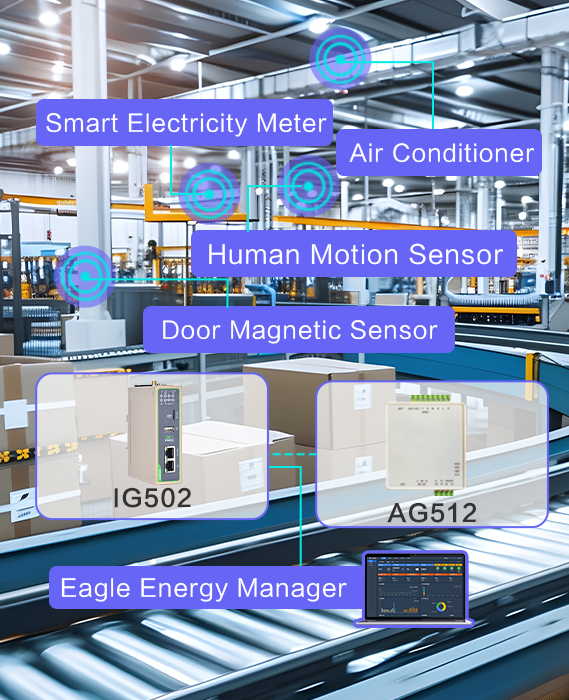

Stellen Sie Sensoren bereit, um die Bedingungen der Klimaanlage zu überwachen, beispielsweise die Anwesenheit von Personen und den Fensterstatus.

AC-Betriebsverfolgung

Bieten Sie eine Lösung zur Überwachung des Betriebs und Stromverbrauchs der Klimaanlage, einschließlich Ein-/Aus-Status und Betriebstemperatur.

Energieverbrauchsanalyse

Ermöglicht die Kategorisierung und detaillierte Analyse des Energieverbrauchs nach Abteilungen, einschließlich Tools für YoY- und MoM-Vergleiche zur Erkennung von anormalem Verbrauch.

Energiesparstrategien

Implementieren Sie Strategien wie das automatische Ausschalten der Klimaanlage, wenn Fenster geöffnet sind oder der Bereich nicht belegt ist, um Kosten zu senken.

Lösung

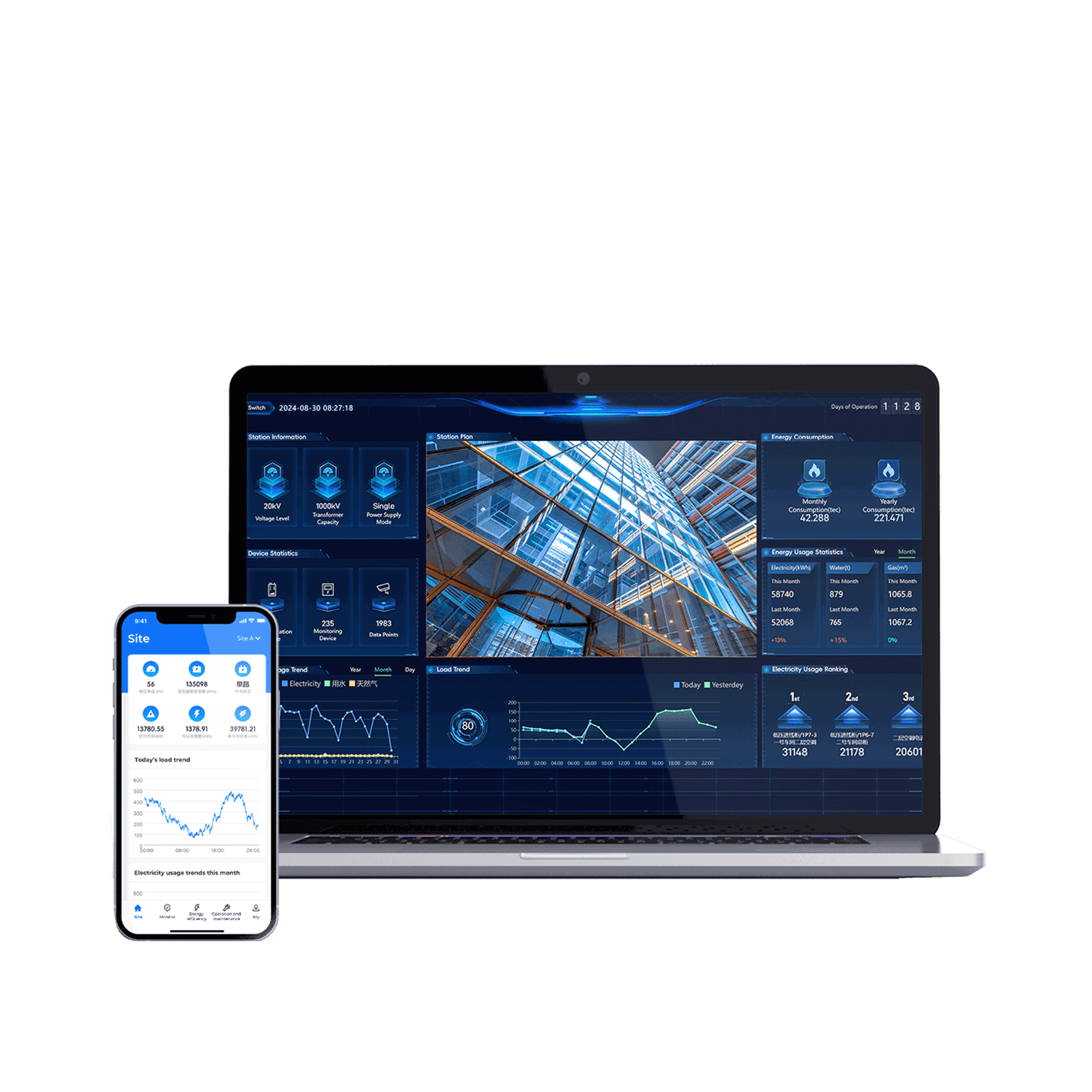

Mit der xEnergy-Lösung von InHand Networks kann die Fabrik ihren Energieverbrauch transparent verwalten und analysieren und abteilungsspezifische Energiesparziele festlegen, um Kosten zu senken und die Wettbewerbsfähigkeit zu steigern.

Der AG512 konvertiert Klimaanlagendaten, die vom IG502 erfasst und zur Visualisierung, Analyse und Einsparung in den Eagle Energy Manager hochgeladen werden. Manager können den Energieverbrauch nach Abteilungen mithilfe von Tools wie Energieflussdiagrammen und Jahresvergleichen analysieren. Abteilungsleiter können Strategien wie Temperatureinstellungen und automatische Abschaltungen konfigurieren und den Klimaanlagenstatus über mobile Geräte fernüberwachen.

Vorteile

Verbesserte Managementeffizienz

Eagle Energy Manager bietet Tools wie Energieflussdiagramme, MoM/YoY-Vergleiche und Abweichungsanalysen, um die Energiedatenanalyse zu automatisieren und präzise Energiesparziele festzulegen.

Kostengünstige Strategien

Intelligente Strategien, wie beispielsweise die automatische Steuerung der Klimaanlage, reduzieren Abfall und Energieverbrauch um bis zu 30%, zugeschnitten auf die Bedürfnisse der Abteilungen.

Effizientes Monitoring

xEnergy bietet umfassende Datenvisualisierung und Echtzeitüberwachung für Geräte wie Zähler und Klimaanlagen und gewährleistet so eine effektive Geräteüberwachung.

Optimierte Implementierung

xEnergy bietet eine Komplettlösung, die Software und intelligente Geräte integriert und so das Projektmanagement und die Projektausführung vereinfacht.