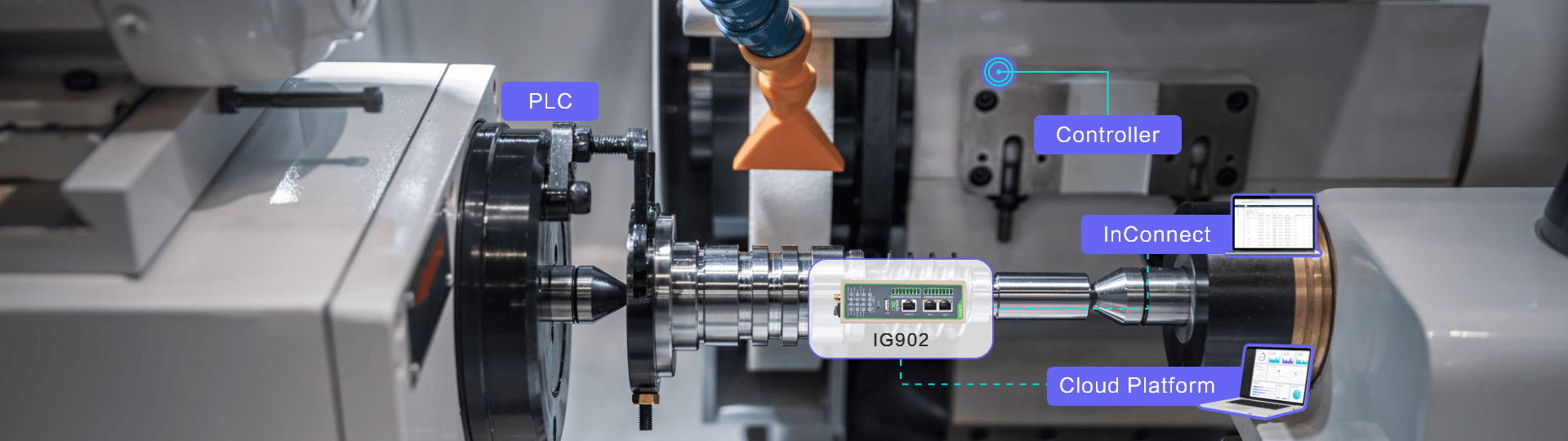

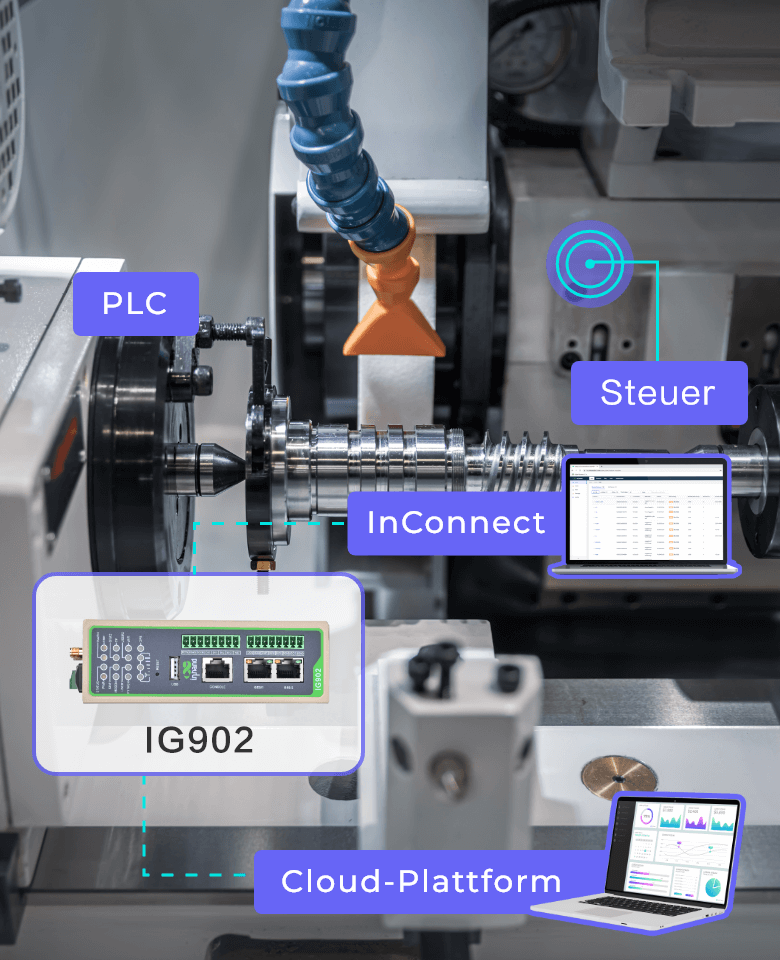

Fernüberwachung von CNC-Maschinen

CNC-Maschinen (Computerized Numerical Control) gewinnen in der industriellen Automatisierung zunehmend an Bedeutung. Das IoT-Edge-Gateway IG902 bietet schnelle und zuverlässige Vernetzung, Python-Programmierung und industrietaugliches Design und bietet eine Fernüberwachungslösung für CNC-Maschinen, die sowohl manuelle Arbeit als auch Kosten deutlich spart.

Hintergrund

Die moderne Bearbeitung hat sich deutlich weiterentwickelt und zeichnet sich durch höhere Komplexität, Präzision, Maschinengröße und Automatisierung aus. CNC-gesteuerte Werkzeugmaschinen (Computerized Numerical Control) sind für die Verbesserung von Bearbeitungsqualität und -effizienz von entscheidender Bedeutung.

CNC-Maschinen sind jedoch teuer, und jede Beschädigung, verringerte Produktionseffizienz oder ein Produktionsstopp kann zu erheblichen Verlusten führen. Um den ordnungsgemäßen Betrieb zu gewährleisten und die vorbeugende Wartung von CNC-Maschinen in verschiedenen Fertigungsanlagen zu ermöglichen, suchte ein Werkzeugmaschinenhersteller nach einer Fernüberwachungslösung.

Kundenanforderungen

Fernüberwachung und -betrieb

Überwachen Sie CNC-Bearbeitungszentren in Echtzeit, einschließlich Produktionsstatus, Werkzeugzustand und Bearbeitungsprozessen. Dies erleichtert die Fernsteuerung und -wartung zur Optimierung von Produktionsplänen.

Verbesserte Produktionseffizienz

Reduzieren Sie durch Fernüberwachung die Ausfallzeiten der Geräte, steigern Sie die Produktionseffizienz und stellen Sie die rechtzeitige Fertigstellung der Produktionspläne sicher.

Werkzeug- und Verbrauchsmaterialverwaltung

Implementieren Sie die Fernüberwachung von CNC-Werkzeugen und Verbrauchsmaterialien, einschließlich Lebensdauervorhersage, Warnmeldungen und automatisierter Nachbestellung. Dies zielt darauf ab, die Bestandsverwaltung zu optimieren und Produktionsunterbrechungen zu minimieren.

Anomalieerkennung und Warnungen

Richten Sie einen Mechanismus zur Anomalieerkennung ein, um den Echtzeitstatus des CNC-Bearbeitungszentrums zu überwachen. Dank rechtzeitiger Warnungen und Benachrichtigungen können Sie umgehend Maßnahmen ergreifen und so potenzielle Verluste reduzieren.

Lösung

Mithilfe des IG902-Edge-Gateways verbindet das Fernüberwachungssystem an verschiedenen Industriestandorten verteilte CNC-Maschinen mit der Cloud-Plattform, um den Betriebsstatus der Maschinen, den Verschleißgrad anfälliger Teile und Daten der elektrischen Steuerungssysteme zu erfassen und zu analysieren.

Der IG902 wurde entwickelt, um Edge Computing zu unterstützen und Datenerfassung, Datenüberwachung, Datenfilterung, Datenbereinigung, Datenschutz, Datenspeicherung, Datenübermittlung und Logikverarbeitung am Front-End durchzuführen, wodurch die erforderliche Kommunikationsbandbreite zwischen Industriestandorten und dem zentralen Überwachungszentrum reduziert und das Cloud-Computing-System optimiert wird.

Das IoT-Edge-Gateway IG902 ermöglicht eine zuverlässige Kommunikation mit geringer Latenz zwischen CNC-Maschinen und dem Cloud-Center. Ingenieure können den Betrieb der Maschinen in Echtzeit überwachen, schneller auf Störungen reagieren und vorbeugende Wartung planen. Dies spart erheblich Personal und Kosten.

Vorteile

Schnelle, sichere und zuverlässige Konnektivität

Das IG902-Gateway ist mit LTE CAT4/CAT1-Mobilfunknetzen, WLAN und Kabelverbindung, mehreren Link-Redundanztechnologien und Sicherheitsstrategien verfügbar und bietet schnellen, sicheren und unterbrechungsfreien Netzwerkzugriff, sodass die Geräte ständig verbunden sind.

Einfache Konfiguration der Datenerfassung

Das IG902 IoT-Edge-Gateway unterstützt mehrere SPS-Protokolle und die wichtigsten IoT-Clouds. Geräte vor Ort können durch eine einfache Konfiguration in wenigen Minuten mit der Cloud verbunden werden.

Leistungsstarke Rechenleistung und intelligente Verarbeitung

Das IG902-Gateway ist mit einem ARM Cortex-A8-Prozessor ausgestattet und bietet leistungsstarke Edge-Computing- und Datenanalysefunktionen. Von SPSen erfasste Daten können am Edge vorverarbeitet werden, was die Cloud entlastet und gleichzeitig die Reaktion auf die Datenquelle beschleunigt.

Alle Industriedesigns

Das industrielle IoT-Gateway IG902 erfüllt die Anforderungen der Industrieklasse, darunter EMV-Klasse 3, IP30 und einen breiten Betriebstemperaturbereich. Es ist robust und langlebig und hält den rauen Umgebungsbedingungen von Industriestandorten stand.