Fernüberwachungslösung für Roboter

With advanced edge computing capabilities, the IG502 IoT edge gateway pre-processes, filters, and cleans streaming data before uploading to the cloud, reducing data center workload and boosting operational efficiency.

Hintergrund

Traditional robot monitoring systems rely heavily on manual inspections and operations, resulting in limited real-time responsiveness, human errors, safety risks, and high labor costs. These challenges are further amplified in harsh environments such as high temperatures, high pressures, or hazardous areas.

To overcome these limitations, the remote monitoring solution of industrial robots leverages advanced robot technology, remote monitoring, and control capabilities. This innovative solution enables seamless remote operations, monitoring, and management of connected robots, offering a comprehensive, efficient, and safer approach to industrial challenges.

Kundenanforderungen

Operative Einblicke in Echtzeit

Achieve real-time monitoring and remote management of industrial robots, providing instant visibility into status, production line conditions, and performance. This enables efficient production planning and scheduling for enhanced productivity.

Störungsvorhersage und Frühwarnung

Continuously collect operational data and sensor information to monitor performance and detect potential faults or anomalies. Issue early warnings to operators or maintenance teams, minimizing downtime and extending the lifespan of connected robots.

Sicherheit und Verlässlichkeit

Ensure robust system security and data integrity to protect industrial robots and their operational data. Safeguard the confidentiality of robot information while maintaining production line continuity.

Lösung

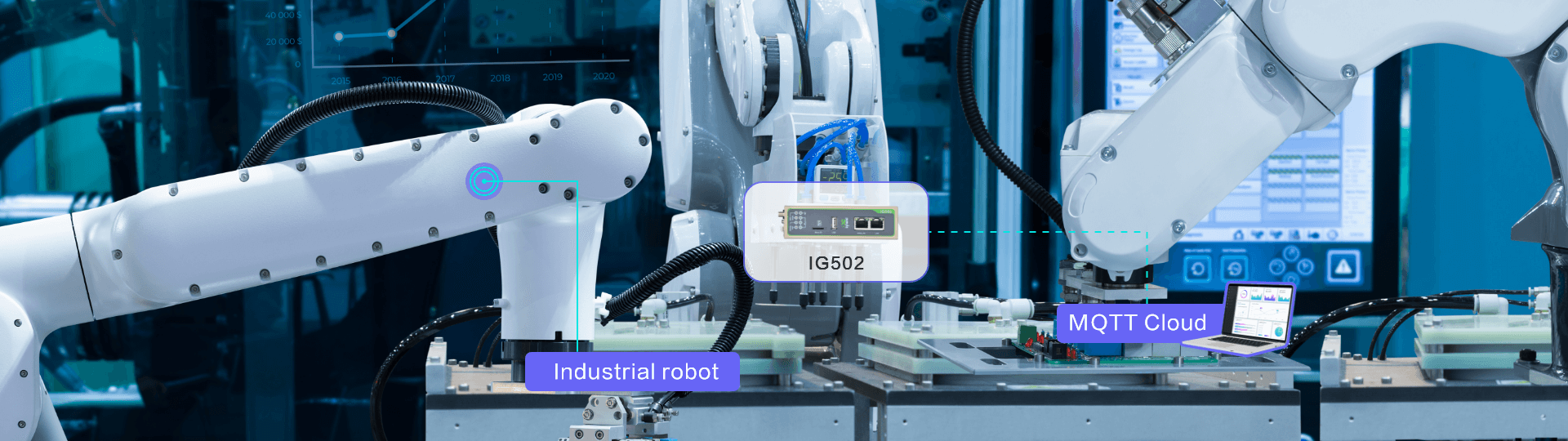

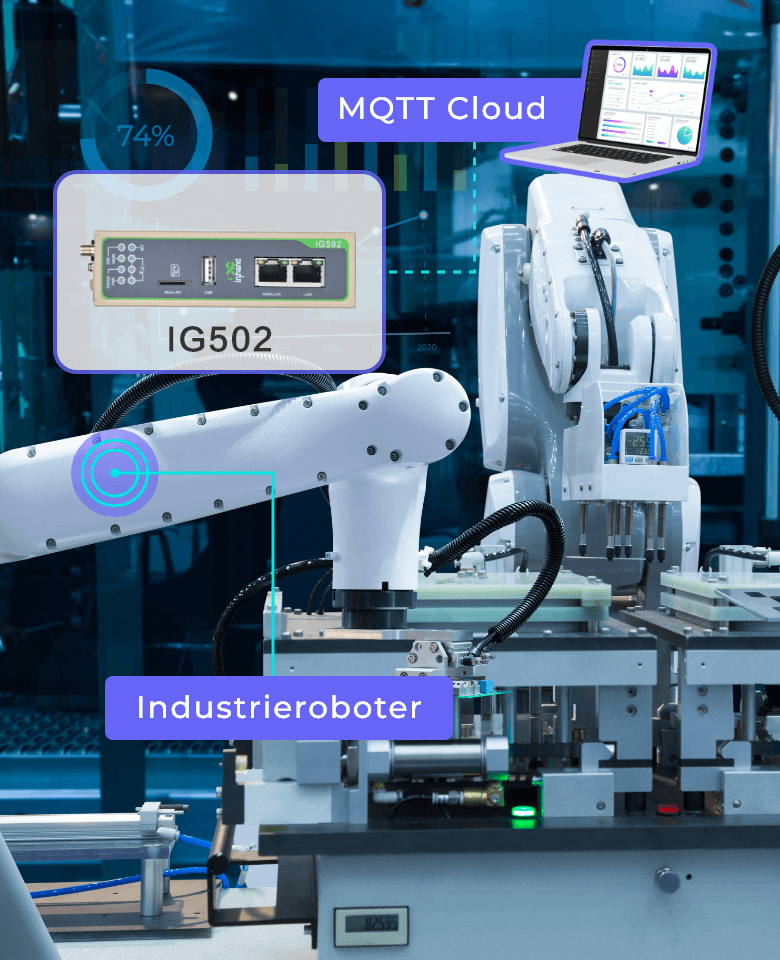

InHand’s Smart Robot Remote Monitoring Solution meets the demands of industrial robot networking and remote intelligent management, significantly improving operational efficiency.

The system includes a robot controller, the IG502 IoT edge gateway, and a remote monitoring platform. The IG502 connects to the robot controller, collecting and transmitting data seamlessly. With robust edge computing capabilities, it supports various industrial protocols and major IoT cloud platforms, simplifying project deployment and lowering costs.

On-site data is pre-processed by the IG502 gateway to reduce cloud load and enable faster responses to on-site events. Filtered data is sent to the remote monitoring platform for real-time viewing, analysis, fault prediction, and remote maintenance. This ensures safe, reliable operations of connected robots and boosts overall efficiency.

Vorteile

Kontinuierliche Konnektivität

Equipped with 4G LTE, Wi-Fi, and wired connections, along with link redundancy technologies, the IG502 IoT edge gateway ensures reliable and uninterrupted network transmission for seamless device operation.

Protocol and Cloud Compatibility

The IG502 supports major industrial protocols like Modbus TCP/RTU, EtherNet/IP, ISO on TCP, and OPC UA Client, enabling easy data transmission to IoT cloud platforms for remote monitoring and preventive maintenance. This reduces operational costs and enhances customer satisfaction.

Leistungsstarkes Edge Computing

The IG502 is equipped with a powerful ARM Cortex-A8 processor, running at 600MHz with 512MB RAM and 8GB eMMC. This robust edge computing capability enables intelligent data processing, optimization, real-time response, and smart analytics for on-site devices.

Python programmierbar, gebaut für Entwickler

The IG502 industrial IoT gateway comes with an embedded development platform that supports Python programming, enabling customers to effortlessly implement specific business logic and achieve personalized functions or services.

Easy Large-scale Management

The IG502 supports web interface configuration and enables easy setup. The Device Manager zentralisiert effizient die Verwaltung zahlreicher Geräte und ermöglicht es den Benutzern, den Status des Gateways jederzeit und überall zu überwachen.