Remote Monitoring of Urban Heat Supply System

In an era where a low-carbon economy is advocated, energy supply must be highly efficient. In light of this, InHand Networks offers a remote networking monitoring solution for heat supply using the IG902 IoT edge gateway, which enables users to oversee the operation status of the heat supply system, and acquire accurate and effective data, thus ensuring the secure and stable operation of the devices.

Background

During the winter, cities face rising demand for quality heat supply. With energy scarcity, improving heat supply while saving energy is urgent. The expanding heat supply network and dispersing worker stations make monitoring and managing operation data challenging for better economic efficiency and heat resource utilization.

In response, InHand Networks offers a remote monitoring solution for heat supply. This solution oversees the operation status, provides accurate data for the heat department, improves heat utilization efficiency, and ensures devices’ secure and stable operation.

Customer Requirements

Real-time Monitoring

It is necessary to promptly obtain real-time information on key parameters of the heating station, such as temperature, pressure, flow rate, etc., to ensure the normal operation of the system.

Easy Deployment across Areas

Simple and swift setup in designated zones with user-friendly hardware and easy installation, reducing deployment complexities.

Secure and Reliable Communications

Robust communication with redundancy mechanisms ensures uninterrupted data transmission to the central monitoring center.

Reliable Long-Term Operation in Unattended Environments

Design durable hardware resistant to environmental factors, coupled with energy-efficient components, for consistent, long-term operation in unattended or challenging settings.

Solution

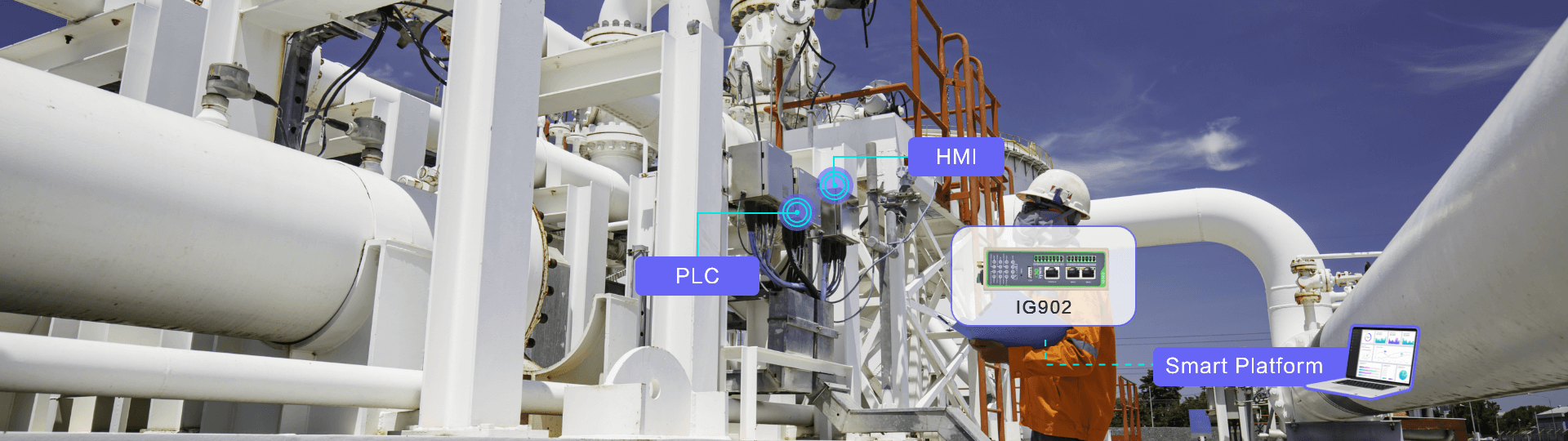

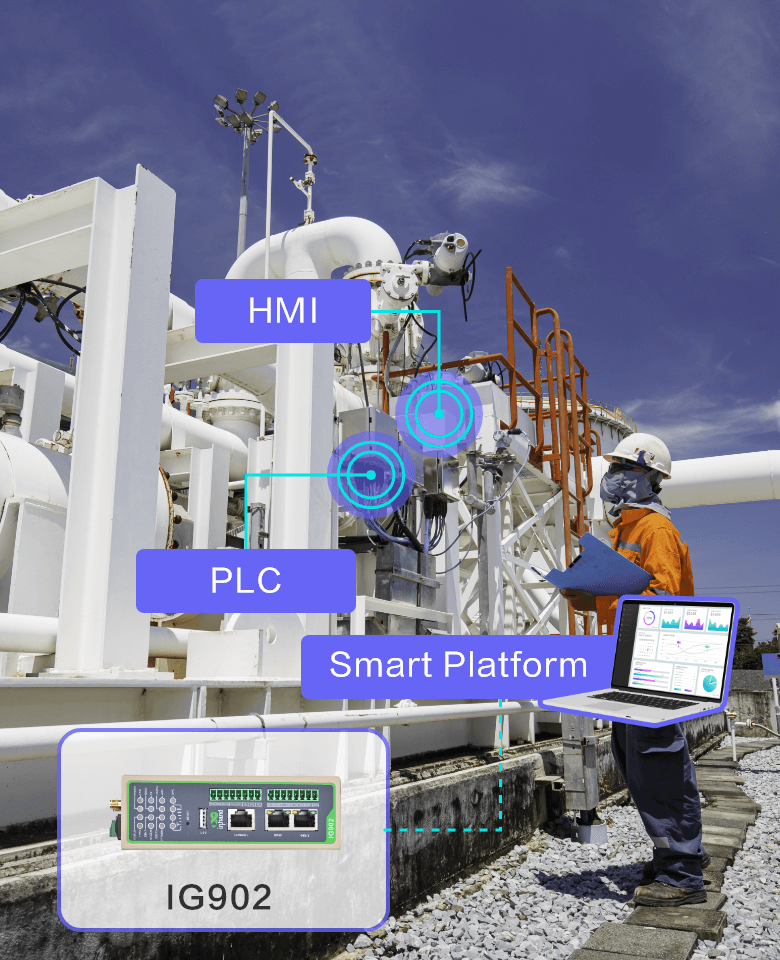

The on-site IG902 edge computing gateway connects to the heat supply station’s PLC and HMI for data collection, then uploads data from heat exchange stations to the cloud via MQTT protocol.

The remote smart heat network platform monitors heat exchange stations, records alarms, performs statistical analysis, manages reports, and handles system administration and BI demonstrations. This B/S architecture platform is accessible from PCs, mobile phones, and tablets.

It manages heat supply station data, including inlet/outlet water temperatures and pressures, compressor status, leakage, temperature thresholds, activation status, and alarms. This solution streamlines traditional manual management, allowing control parameters to be uploaded to the cloud for real-time fault detection and resolution. This reduces user waiting times and operation costs, enhancing client satisfaction.

Capabilities

High-speed, Secure, and Reliable Connectivity

The IG902 edge computing gateway is available with LTE, Wi-Fi, and wired connections. It incorporates multiple link redundancy technologies to ensure a consistently high-speed and reliable network connection.

Supports Major Industrial Protocols and Clouds for Easy Monitoring

The IG902 supports major PLC protocols, making it easy to send device data to the cloud for remote monitoring and preventive maintenance, reducing operational costs and improving customer satisfaction.

Edge Computing Enabled in the Cloud

With support for Microsoft Azure and AWS Greengrass clouds, the IG902 IoT edge gateway makes it easy to process data on the cloud. Customers can program their own applications according to business needs.

All Industrial Design

Meeting industrial grade on indexes including EMC grade 3, IP30, and wide operating temperatures, the IG902 is solid and durable to withstand the harsh environmental conditions of industrial sites.