Intelligent Concrete Mixing Station Solution

The IR915 industrial LTE router connects one or more field PLCs to form a network of concrete mixing equipment, collecting data from field controllers and sensors. It uploads the data intelligently with a local caching mechanism, ensuring data reliability, real-time transmission, and security while reducing data flow costs.

Background

As large-scale infrastructure projects expand, the demand for concrete mixing equipment in the construction industry is growing rapidly. The technical performance of this equipment directly influences project quality and lifespan.

However, maintaining concrete mixing stations poses several challenges. Routine upkeep, timely inspections, repairs, and component replacements require substantial effort. Traditional maintenance often relies on manufacturers’ service departments at distributed locations or involves on-site visits by company staff, leading to increased after-sales costs for manufacturers and significant disruptions to equipment users’ production schedules.

Customer Requirements

Improved Productivity

Enhance productivity and optimize workflows. Real-time monitoring and remote management reduce human intervention and errors, enabling automated control and adjustments, thus boosting production line performance and output.

Smart Management

A smart management system enhances efficiency and decision-making accuracy. Centralized data storage and analysis, powered by big data and AI technologies, facilitate data mining and predictive analysis, providing reliable insights for decision-making.

Better Safety and Reliability

Real-time monitoring of equipment operation and key parameters allows prompt identification of anomalies and proactive alerts, minimizing risks of accidents and failures, and improving equipment reliability and operational safety.

Solution

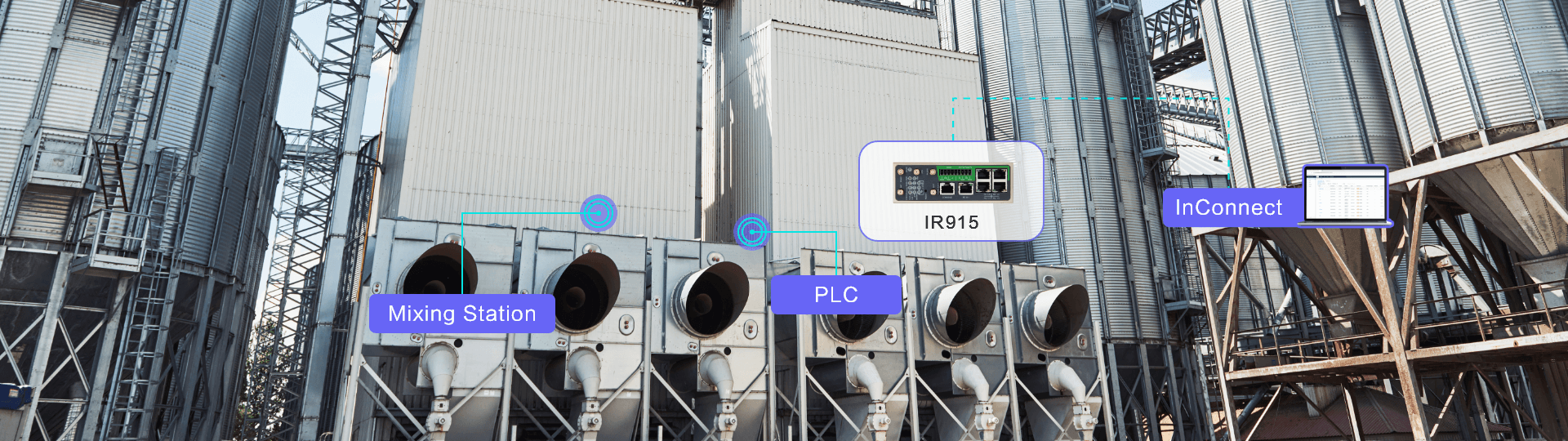

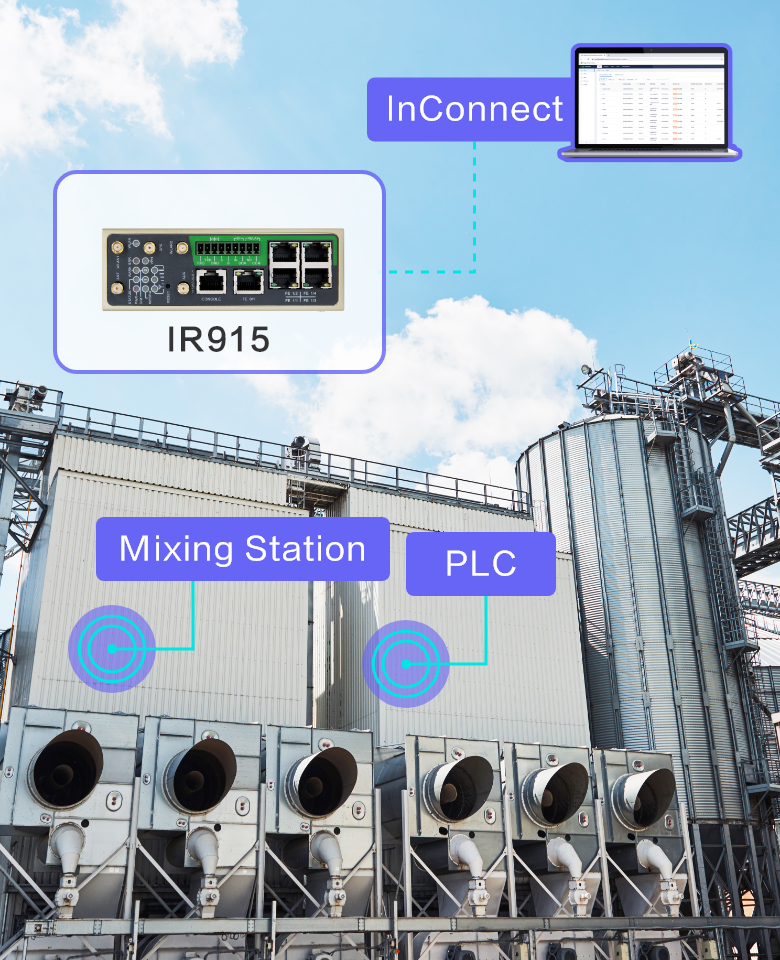

InHand delivers a remote maintenance system for concrete mixing equipment based on PLC and wireless communication technology. Leveraging the advanced industrial router IR915 industrial router, this solution enables real-time remote diagnostics, warnings, and maintenance of the mixing equipment, even when operators are away from the production site.

The online system consists of PLCs, the IR915, and a monitoring center. The IR915 router establishes local networks with one or multiple on-site PLCs, securely transmitting real-time data to the monitoring center for analysis and management.

Maintenance engineers can establish a secure tunnel between the on-site PLC and the InConnect remote access service. This enables them to perform fault diagnosis, remote updates, and modifications of controller programs for production line hardware, ensuring smooth operations.

Capabilities

Reliable, Uninterrupted Network Communication

With link backup and VRRP technology, the solution ensures fault-tolerant links and 24/7 online operation. With dual SIM, it enables multiple carrier network options and ensuring continuous data transmission through dual-network redundancy.

Industrial-grade Design, Resilient in Harsh Environments

Built with high-standard components, the IR915 industrial router ensures stable operation in extreme conditions with its robust metal casing, fan-less cooling, IP30 protection, wide temperature and voltage ranges, and high EMC rating.

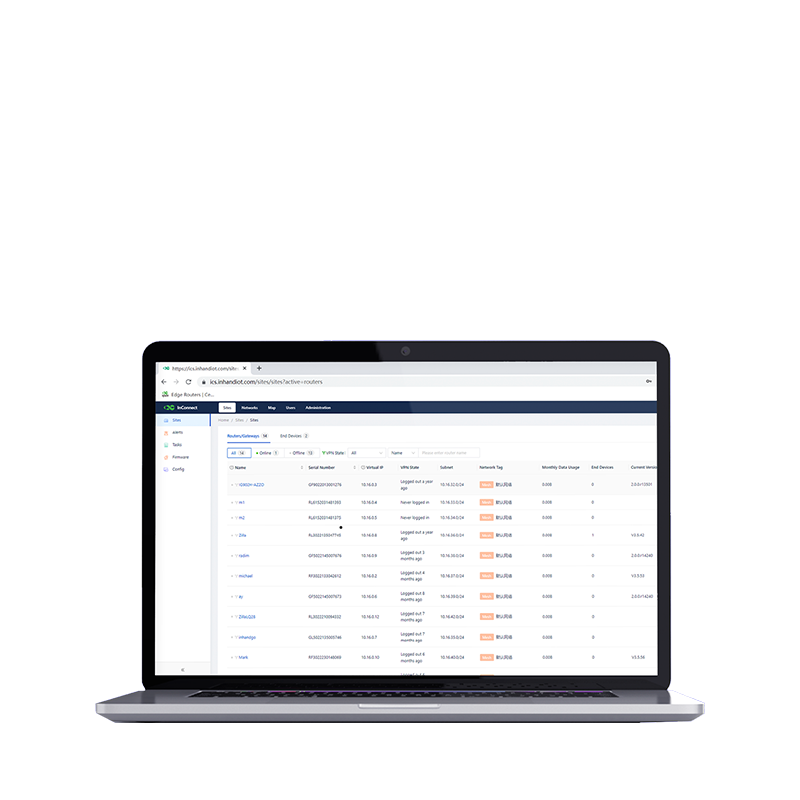

Unified Cloud Platform, Effortless Remote Maintenance

Integrating the InConnect remote access service, the solution allows real-time management of thousands of distributed site devices. It facilitates remote deployment and maintenance, and provides full control of on-site operations, making management easier, more efficient and cost-effective!

Globally Certified, Globally Applied

The IR915 industrial LTE router is globally certified, meeting CE, FCC, UL, PTCRB, CCC, Verizon Wireless, and AT&T standards.