Predictive Maintenance for Industrial Generators

InHand Networks provides a predictive maintenance solution for industrial generators, combining real-time monitoring, intelligent data analysis, and remote management to enhance reliability, reduce costs, and boost operational efficiency.

Background

The U.S. economy depends heavily on generator manufacturers serving nearly every industry. Power outages can lead to inventory loss, equipment failure, disrupted just-in-time deliveries, and financial losses in the millions. To address these risks, a leading generator manufacturer aims to reduce unplanned downtime, lower maintenance costs, enhance operational efficiency, and improve customer satisfaction and equipment safety by adopting a predictive maintenance solution.

Customer Requirements

Real-Time Monitoring

Monitor industrial generator parameters, including temperature, vibration, voltage, and current, in real time via a sensor network.

Data Analysis

Perform intelligent data analysis to provide actionable recommendations for operational improvements.

Remote Management

Enable remote monitoring and management of industrial generators with real-time health alerts.

Predictive Maintenance

Optimize maintenance schedules for industrial generators to reduce downtime and operational costs.

Solution

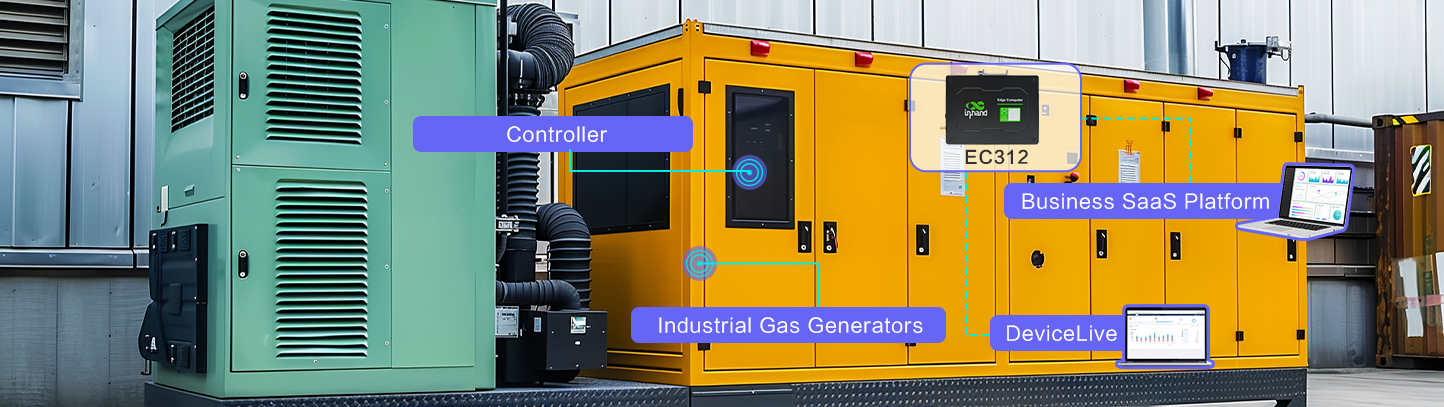

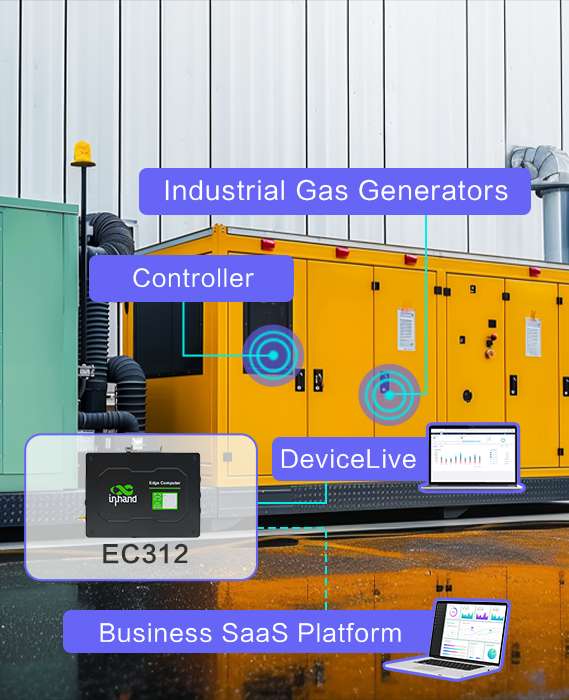

InHand Networks deployed a predictive maintenance solution leveraging the EC312 edge computer and IoT technologies. This ARM-based Linux industrial computer connects to industrial generator controllers, using an Azure IoT Edge application to monitor real-time parameters such as temperature, vibration, pressure, and current. The EC312 processes and analyzes data locally, minimizing latency and providing real-time alerts for anomalies to the maintenance team. Data is securely transmitted to the cloud, enabling safe and reliable remote connectivity.

By implementing this predictive maintenance solution, the customer enhanced the reliability, performance, and remote monitoring of their industrial generators while achieving significant cost savings and improved customer satisfaction.

Benefits

Easy Customization

Powered by a standard Linux operating system, the EC312 edge computer enables seamless customization and installation of third-party edge applications.

Reliable Global Connectivity

The EC312 edge computer supports worldwide cellular networks for convenient and efficient real-time connectivity anywhere.

Compatibility with Various Generator Models

The EC312 edge computer features extensive interfaces (e.g., AIN, CAN) for easy integration, even with older industrial generator models.

Industrial-Grade Performance

Equipped with super capacitors, the EC312 edge computer ensures uninterrupted operation during power switchovers within 500ms.

Simplified Remote Management

With InHand DeviceLive, users can efficiently manage edge applications and monitor generators at scale through the cloud.