5G Remote Monitoring Solution for Industrial Robots

Connecting industrial robots to the IR624 5G industrial router enables seamless data transmission for analysis and maintenance planning. With high-speed 5G, stable connectivity, and cloud management, the IR624 5G router is perfect for industrial IoT deployment.

Background

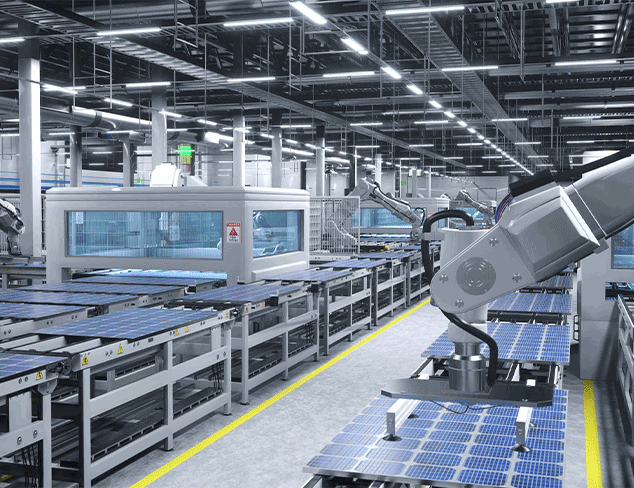

With the rise of industrial automation and increased use of industrial robots, the manufacturing sector demands higher production line stability and efficiency. Traditional on-site monitoring methods face challenges such as geographical limitations, lack of real-time monitoring, and insufficient diagnostic capabilities. This has created an urgent need for flexible and efficient solutions like remote monitoring of industrial robots.

Customer Requirements

Real-time Monitoring and Data Collection

The factory requires real-time monitoring of industrial robots, including operational status, work efficiency, production speed, and fault conditions, while collecting key production data for analysis.

Fault Warning and Remote Diagnosis

The solution must deliver fault warnings, promptly detecting potential issues and enabling remote diagnosis to help engineers quickly identify and resolve problems.

System Stability and Reliability

A stable and reliable remote monitoring solution is essential, ensuring continuous operation over long periods and supporting the longevity of the production line.

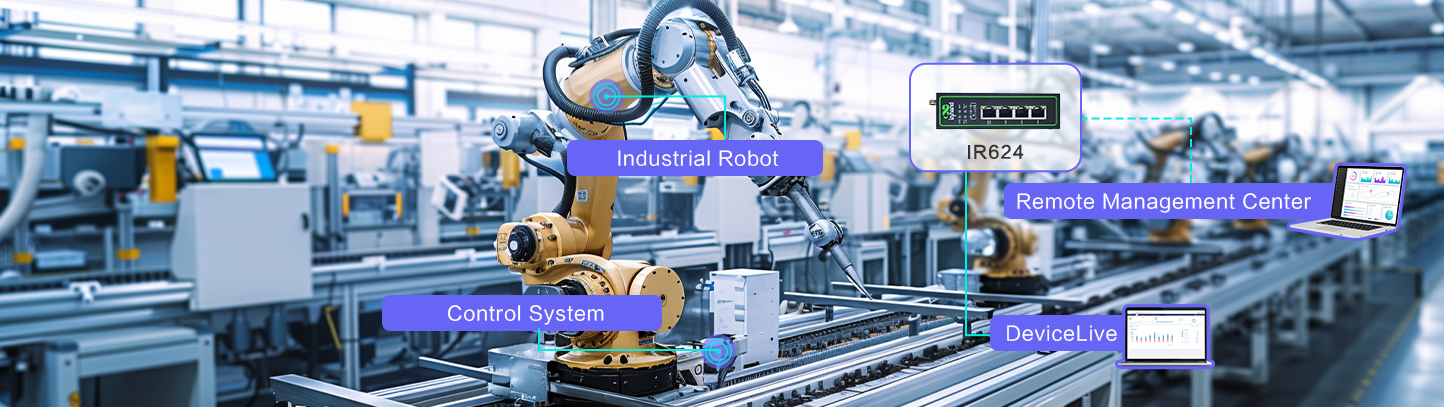

Solution

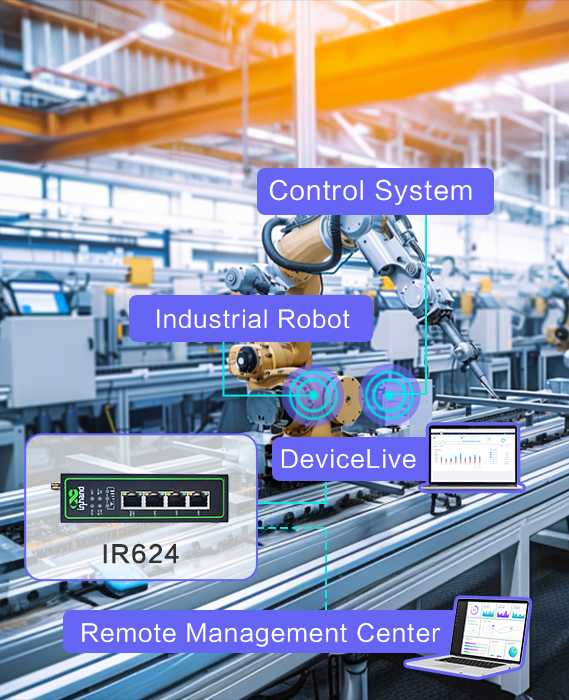

ndustrial robots comprise a robot arm, drive system, control system, and human-machine interaction system. The controller, PLC, and human-machine interaction system connect to the IR624 5G industrial router via Ethernet or serial port. The IR624 enables high-speed data transmission, sending real-time robot status to the remote robot data center through a reliable 5G network. The data center analyzes status information, production capacity, and fault alarms in real-time, supporting predictive maintenance and repair planning. For remote maintenance, devices can be managed and operated seamlessly through the InHand DeviceLive platform.

Benefits

High-Speed 5G Connectivity

The IR624 supports high-speed, low-latency 5G cellular networks, enabling real-time transmission of industrial robot status data for efficient monitoring and management.

Rich Industrial Interfaces

Equipped with four Gigabit Ethernet ports, RS232, and RS485 interfaces, the IR624 5G router supports seamless integration with industrial robots featuring diverse interface requirements.

“Always Online”

Features like link detection, link backup, and dual SIM card switching ensure stable and uninterrupted network connectivity. The built-in watchdog enables fault self-recovery, maximizing uptime for industrial IoT applications.

Simplified Cloud Management

Integrated with the DeviceLive platform, the IR624 allows centralized management of thousands of devices, establishes secure connections with remote devices, and streamlines remote operation and maintenance processes.

Industrial-Grade Design

Built with rugged industrial design principles, the IR624 operates reliably in harsh environments, making it ideal for various IoT and industrial robot deployment scenarios.