Solución de automatización de fábricas 5G

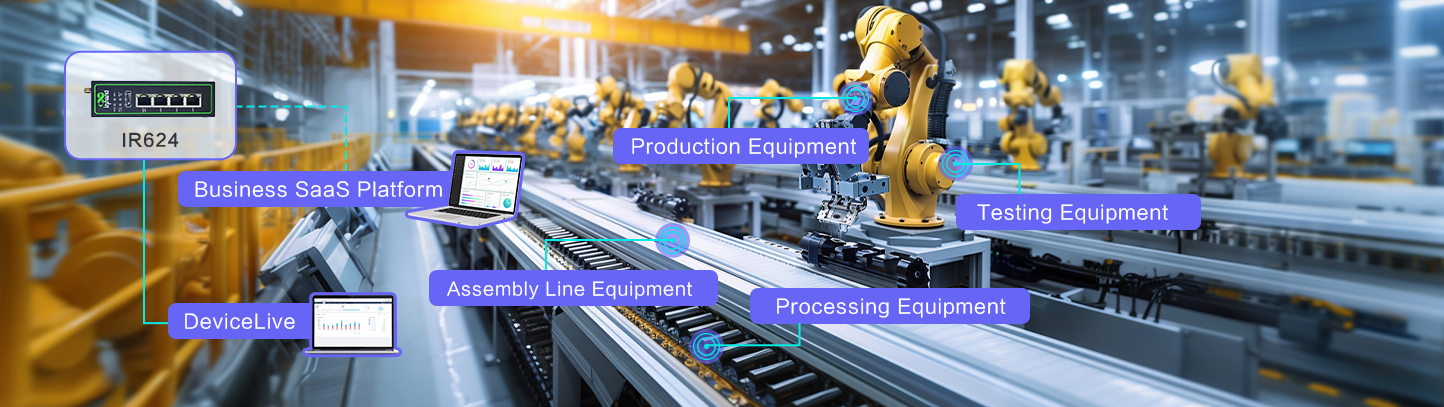

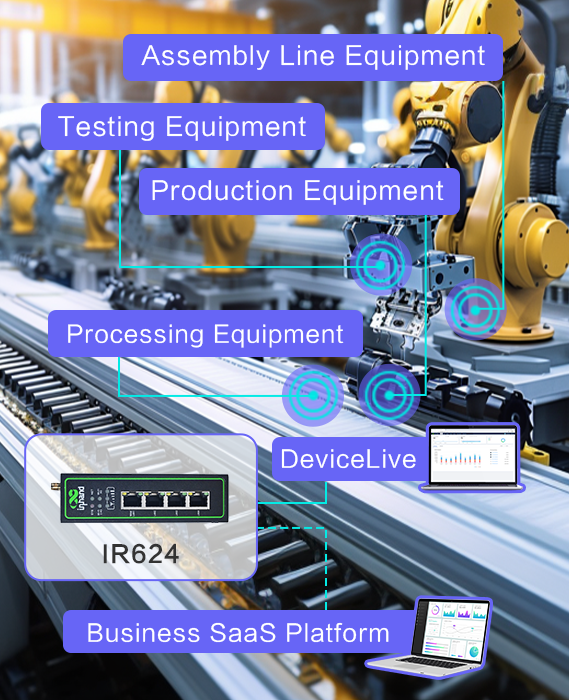

5G Smart factories are enhancing manufacturing efficiency with IoT and AI. The smart factory leverages 5G connectivity through DeviceLive for stable networks, remote monitoring and secure data transmission. Overall, these features are all met by the IR624 with its diverse industrial interface and robust security.

Contexto

With the rapid development of information technology, the Internet of Things, artificial intelligence, and other fields, smart factories are a key focus for upgrading and transforming the manufacturing industry. In smart factories, real-time communication and collaborative operation among production line equipment can enhance automation throughout the production process.

Requisitos del cliente

Improved Production Efficiency

Ensure real-time communication and collaboration among equipment through stable network connectivity to achieve 24-hour continuous production and enhance production efficiency.

Reduced Maintenance Costs

Utilizing remote monitoring and management will identify and resolve risks promptly, reducing the workload of on-site maintenance personnel and lowering maintenance costs.

Business Data Security

Ensure the solution has been optimized with secure network connectivity and data transmission to avoid security issues such as network attacks and business data leakage.

Solución

The production, assembly line, inspection, and process equipment on the production line connect to the IR624 5G industrial router via Ethernet or serial port. The IR624 then transmits the production line data in real-time to the remote business platform using a high-speed 5G cellular network. The business platform utilizes big data to conduct in-depth analysis of the collected production data, providing real-time status of the production line and enabling live monitoring of the production process. Additionally, by utilizing Ethernet ports to locally segment VLANs, the IR624 router interfaces with the factory’s MES system, facilitating tracking of material usage, production progress, and other data. Furthermore, InHand also provides the DeviceLive equipment operation management platform, which establishes remote channels for equipment management and maintenance.

Capacidades

High-Speed Cellular Network

The IR624 industrial router supports high-speed 5G cellular networks, offering high bandwidth and low latency cellular services.

Rich Industrial Interfaces

The IR624 has four Gigabit Ethernet ports, as well as RS232 and RS485 interfaces, meeting the connectivity needs of different devices on the production line.

Robust Security Strategies Safeguarding the Network

The IR624 5G router supports multi-layered security strategies such as VPN, firewall, and policy routing, ensuring data and network security.

“Always Online”

The IR624 5G industrial router supports link detection, backup, dual SIM card switching, and other functions, effectively ensuring stable network connections. Additionally, the built-in watchdog enables fault self-recovery.

Simple Cloud Management

The IR624 router supports the DeviceLive equipment management platform, enabling centralized management of thousands of devices. Furthermore, it can establish secure connection channels with remote devices, facilitating remote operation and maintenance.

Industrial Design, Exquisite Quality

Adhering to consistent industrial principles, the IR624 industrial router is resilient to harsh environmental conditions and is suitable for various IoT deployment scenarios.