Solución integrada de monitoreo de energía en fábricas

InHand Networks’ xEnergy solution optimizes energy management with real-time monitoring, automated reporting, and comprehensive analysis. It enhances maintenance efficiency, reduces costs, and supports sustainability, ensuring regulatory compliance and promoting responsible energy use.

Contexto

Routine factory inspections are vital for safety, but traditional manual methods are time-consuming and inefficient. The lack of transparency in energy use further complicates monitoring and identifying wasteful practices or high-energy equipment. With stricter environmental regulations and the drive toward digital and green transformation, companies must enhance operational efficiency, ensure regulatory compliance, and maintain competitiveness. Implementing an effective energy management solution is key to overcoming these challenges and improving overall performance.

Requisitos del cliente

Environmental Data Reporting

Collect and report environmental data to the relevant agency to ensure compliance.

Real-Time Equipment Monitoring

Monitor distribution room equipment in real-time to enhance reliability and extend equipment lifespan.

Solar Power Analysis

Display solar power data, including generation metrics, carbon reduction, and returns analysis.

Comprehensive Energy Analysis

Analyze energy use by equipment category using various tools and reports, with auto-generated monthly operational reports for better decision-making.

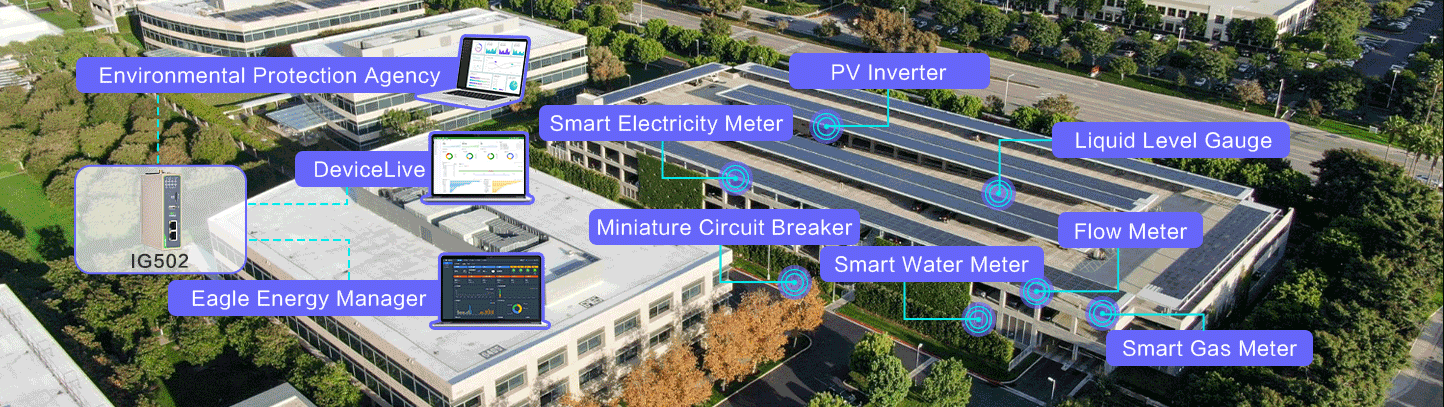

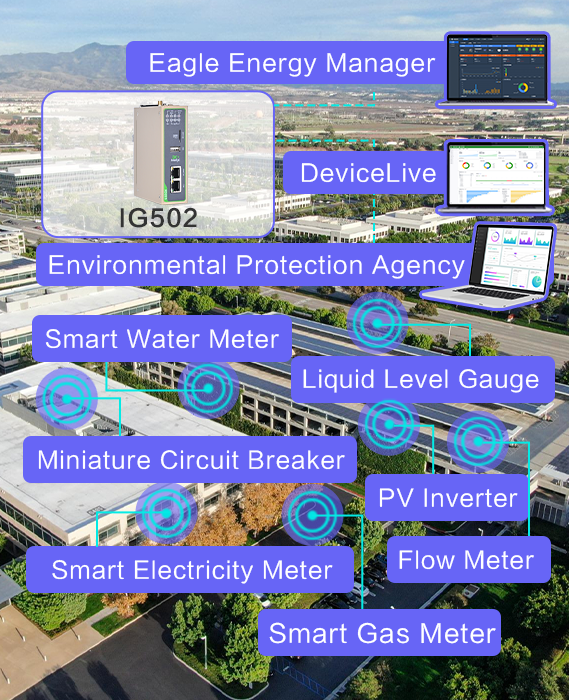

Solución

InHand Networks implemented the xEnergy solution to help achieve transparent data management and efficient energy analysis, ensuring compliance with regulations. The IG502 edge gateway connects meters and circuit breakers, collecting data on electricity, water, and environmental factors. This data is converted and sent to the environmental bureau while also being uploaded to Eagle Energy Manager for visualization and analysis. Maintenance teams monitor equipment in real-time, and managers use the platform for energy analysis, automated reports, and performance insights.

Beneficios

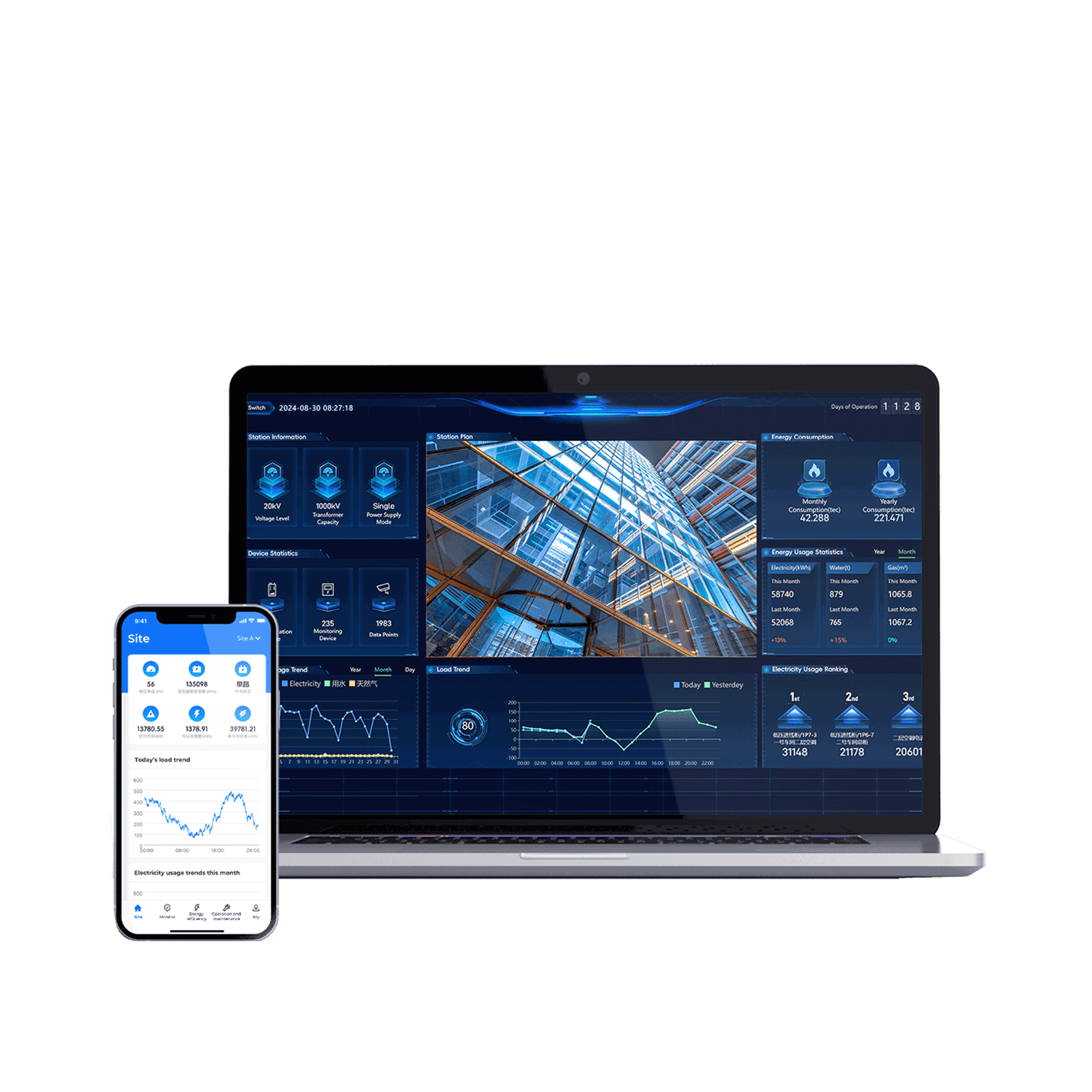

Improved Maintenance Efficiency

Real-time monitoring via Eagle Energy Manager reduces manual inspections with alerts through web, SMS, and email, ensuring timely issue resolution.

Enhanced Management Efficiency

Automated energy and TOU reports streamline data management, with customizable monthly reports improving administrative efficiency.

Cost Savings through Energy Analysis

Detailed energy analysis tools help identify abnormal consumption, optimize operations, and support decision-making for cost reduction.

Compliance and Sustainability

Through real-time environmental reporting and solar energy contributions, xEnergy helps businesses ensure regulatory compliance, obtain green factory certification, and strengthen corporate social responsibility.

Productos

Adaptado para la gestión de energía industrial y de edificaciones.

Puertas de enlace programables de computación en el borde del Internet de IoT

Computadora de borde basada en ARM para aplicaciones de IoT