Línea de Producción Automatizada para Bebidas

El auge del IoT industrial conecta más máquinas y dispositivos in situ a Internet, lo que plantea retos para la recopilación y el procesamiento de datos. La web Puerta de enlace de IoT Edge IG902con sus potentes capacidades de computación de borde, gestiona eficazmente grandes volúmenes de datos, aliviando las cargas del sistema y mejorando la productividad.

Contexto

Con el crecimiento del IoT, la conexión de más máquinas y dispositivos in situ a Internet plantea una cuestión crítica: ¿Cómo podemos garantizar un acceso rápido y fiable al tiempo que minimizamos la carga de la computación en nube a medida que aumenta el volumen de datos?

Los procesos de producción industrial se enfrentan a retos adicionales, como la diversidad de marcas de equipos automatizados, las distintas interfaces industriales, los protocolos incompatibles y la apertura limitada. Cómo superar estas barreras para agilizar la recopilación e integración de datos?

Requisitos del cliente

Visualización en Tiempo Real y Gestión Remota

Permite supervisar y gestionar en tiempo real las líneas automatizadas de producción de bebidas. Los usuarios pueden acceder al estado de los equipos, las métricas de producción y los indicadores clave de rendimiento en cualquier momento y lugar, lo que facilita la toma de decisiones y los ajustes operativos oportunos.

Advertencia de fallas y Mantenimiento predictivo

Emitir avisos de avería para detectar a tiempo fallos de funcionamiento, anomalías y problemas potenciales. Aplique medidas de mantenimiento predictivo para minimizar el tiempo de inactividad, reducir los costes de reparación y mejorar la fiabilidad y productividad de los equipos.

Tomar decisiones y optimizar basándose en datos

Registre los datos operativos de los equipos de la línea de producción, proporcionando funciones de consulta y exportación de datos para apoyar la toma de decisiones informadas. Optimice la utilización de los recursos y permita una toma de decisiones inteligente gracias a una visión precisa de los datos en tiempo real.

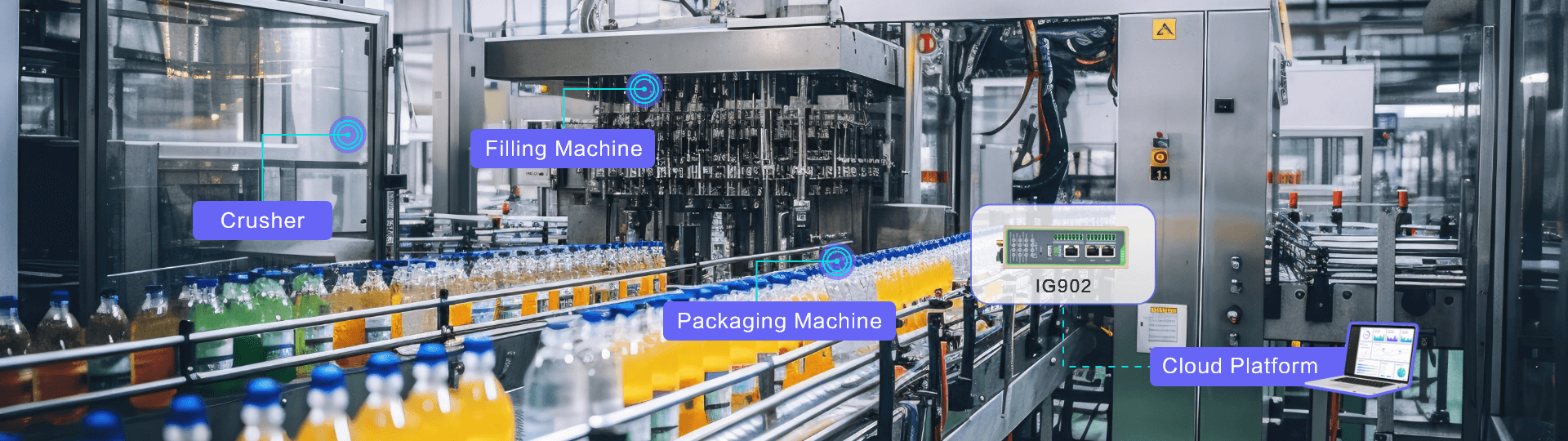

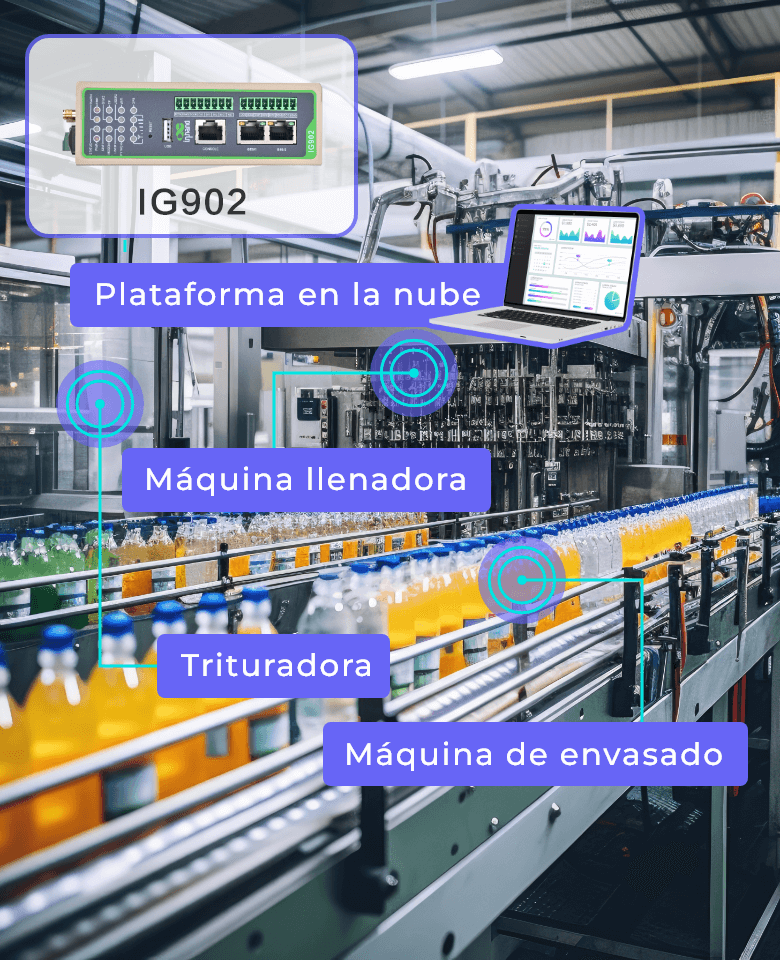

Solución

La línea automatizada de producción de bebidas consta de varias máquinas para distintos procesos, como limpieza, trituración, llenado y envasado de la fruta. El sitio Pasarela informática IG902 recopila datos operativos y de eficiencia de estas máquinas mediante protocolos industriales como Profinet, con funciones como las alarmas SMS para mejorar la supervisión y la capacidad de respuesta.

Robots industriales se encargan de tareas como la clasificación de fruta, el llenado de botellas, el envasado y el apilado. La pasarela realiza un seguimiento en tiempo real de su estado operativo, salud y mejoras de eficiencia mediante protocolos OPC UA, con soporte para la reanudación de la carga de datos tras puntos de interrupción y almacenamiento local seguro de datos.

El sistema transportador transporta materiales y bebidas embotelladas a través de distintas fases de producción. La pasarela adquiere datos sobre las operaciones del transportador a través de protocolos EtherNET/IP, incluidas alarmas IO para la detección de fallos en tiempo real.

El IG902 también admite análisis del consumo eléctricoRecopilación de datos de varias instalaciones de producción mediante protocolos Modbus. Mediante el preprocesamiento y la limpieza de datos, permite obtener información práctica para optimizar el uso de la energía durante la producción automatizada.

Beneficios

Conectividad de alta velocidad, segura y fiable

Equipada con opciones LTE, Wi-Fi y cableadas, junto con tecnologías de redundancia de enlaces, la pasarela IG902 IoT Edge garantiza una transmisión de red continua y fiable, manteniendo los dispositivos en línea para un funcionamiento ininterrumpido.

Protocolo y compatibilidad con la nube para facilitar la supervisión

El IG902 es compatible con protocolos industriales como Modbus TCP/RTU, EtherNet/IP, ISO on TCP y OPC UA Client, lo que permite la transmisión de datos sin interrupciones a plataformas en la nube IoT para la supervisión remota y el mantenimiento predictivo. Esto reduce los costes operativos y mejora la satisfacción del cliente.

Python programable para personalización

El IG902 La pasarela IoT cuenta con una plataforma de desarrollo integrada compatible con programación Python, que permite a los desarrolladores implementar lógica empresarial específica y crear funciones personalizadas con facilidad.

Mantenimiento a distancia eficaz con InConnect

La solución ofrece túneles VPN seguros a través del InConnect para mantenimiento remoto, incluyendo actualizaciones de programas PLC, depuración y ajustes de parámetros, garantizando respuestas rápidas a las averías de los equipos.

Productos

Pasarela IoT multiprotocolo diseñada para aplicaciones de Internet de las cosas (IoT).