Solution de télésurveillance pour les machines de moulage par injection

Grâce à de solides capacités de transmission de données et d'informatique de périphérie, la passerelle IG502 IoT edge gateway permet de surveiller à distance des machines distribuées, de stimuler l'efficacité opérationnelle et de simplifier la maintenance des installations.

Contexte

Les machines de moulage par injection jouent un rôle essentiel dans la production d'une large gamme de produits en plastique. Toutefois, les méthodes de surveillance traditionnelles se heurtent à des difficultés telles que le manque de visibilité du processus, les inspections manuelles limitées et les retards dans la détection des défauts.

Pour surmonter ces limites, une solution de surveillance à distance pour les presses à injecter utilise l'IoT, les plateformes cloud et les technologies de surveillance à distance. Cette solution permet une surveillance en temps réel, une collecte efficace des données et des opérations à distance transparentes, garantissant ainsi une amélioration des performances et de la fiabilité.

Exigences du client

Surveillance en temps réel et contrôle à distance

Surveillez les paramètres clés de la machine de moulage par injection, tels que la température, la pression et la vitesse, par l'intermédiaire d'une plateforme en nuage ou d'un serveur local. Permettre le contrôle à distance pour ajuster les paramètres et améliorer le processus de production.

Diagnostic des pannes et maintenance prédictive

Utilisez un système intelligent pour analyser les données, identifier les défaillances potentielles et envoyer des alertes en temps utile afin d'éviter les retards de production et les dommages aux équipements. La maintenance prédictive assure une maintenance planifiée en fonction de l'état de la machine, réduisant ainsi les temps d'arrêt imprévus.

Analyse des données et rapports

Traitez et visualisez les données opérationnelles à l'aide d'une plateforme avancée. Générer des rapports et des graphiques pour suivre l'efficacité de la production, les mesures de qualité et l'utilisation des équipements, afin d'aider les clients à améliorer continuellement leurs opérations.

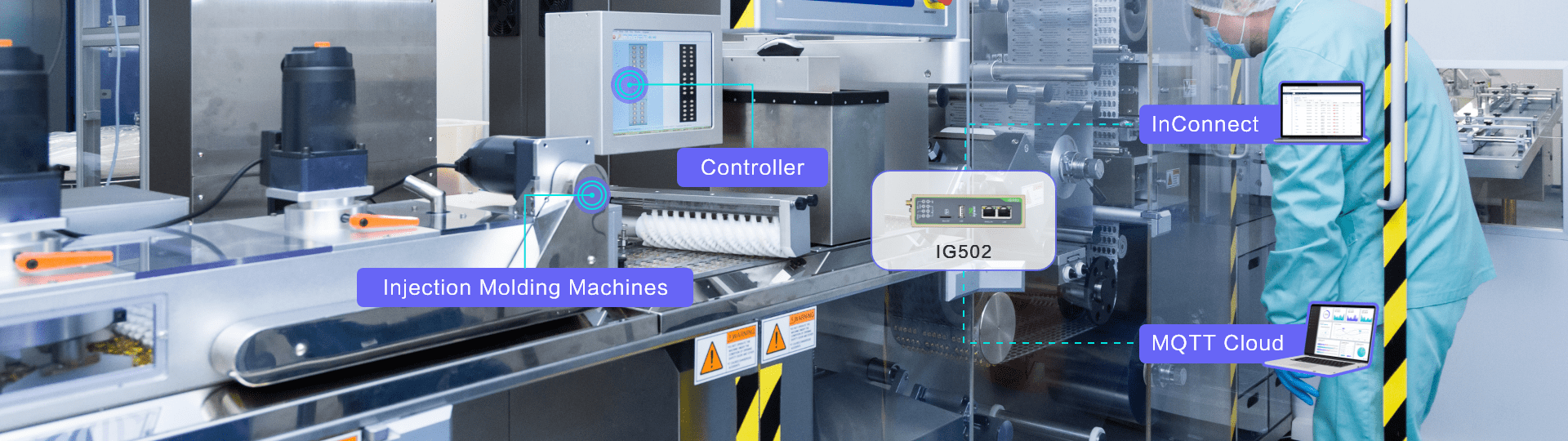

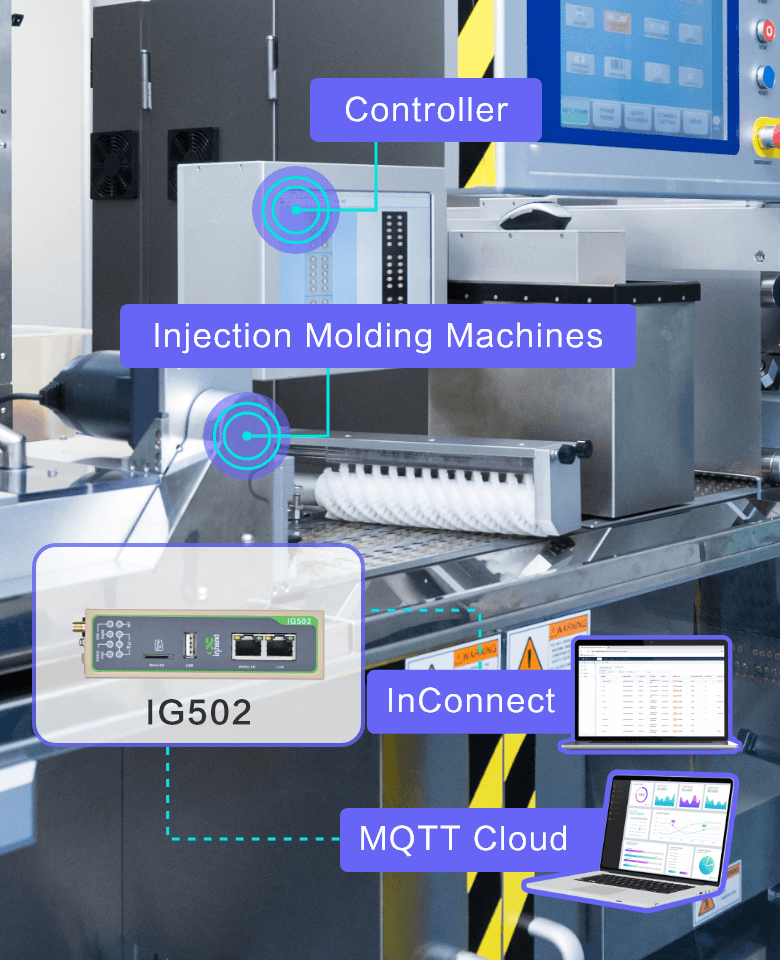

Solution

La solution comprend des machines de moulage par injection, IG502 une passerelle de périphérie IoT et une plateforme de gestion à distance. L'IG502 se connecte au contrôleur de la machine de moulage par injection pour collecter des données sur site en temps réel, telles que la température, la pression et les niveaux de lubrifiant. Après avoir filtré et prétraité les données localement, il transmet les informations à la plateforme de gestion à distance via des protocoles dédiés sur le réseau 4G pour une analyse et un traitement avancés. Les clients peuvent accéder à ces données, les analyser et les gérer à tout moment par le biais d'ordinateurs ou d'appareils mobiles.

Les équipes de maintenance peuvent utiliser la plateforme client pour établir un canal de maintenance avec les machines de moulage par injection sur site. Elles peuvent configurer, déboguer et mettre à niveau l'équipement à distance, ce qui permet une maintenance à distance et une surveillance en temps réel. Cette approche améliore l'efficacité opérationnelle en fournissant une vision immédiate de l'état de la machine. Grâce à la maintenance prédictive, les problèmes sont détectés et résolus rapidement, ce qui réduit les temps d'arrêt et prolonge la durée de vie de l'équipement.

Capacités

Prise en charge des principaux protocoles et nuages

La passerelle IG502 IoT edge gateway fonctionne avec Modbus TCP/RTU, EtherNet/IP, ISO on TCP, OPC UA Client, et plus encore, ce qui simplifie l'envoi des données de l'appareil vers le cloud pour la surveillance à distance et la maintenance prédictive. Cela permet de réduire les coûts et d'améliorer la satisfaction des clients.

Programmation Python pour la personnalisation

L'IG502 comprend une plateforme Python intégrée, permettant aux développeurs d'implémenter facilement une logique commerciale spécifique et de créer des fonctions personnalisées.

Une gestion efficace pour les grands déploiements

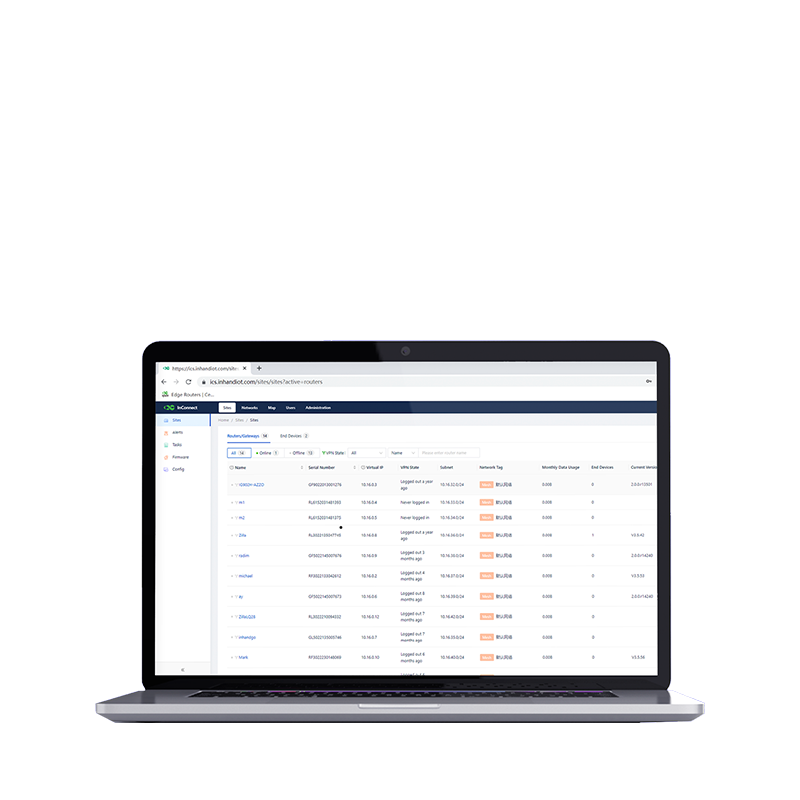

Le IG502 est doté d'une interface web pour une configuration rapide et prend en charge la gestion centralisée avec le Device Manager d'InHand, ce qui permet de surveiller en temps réel plusieurs appareils.

Une connectivité fiable pour un fonctionnement continu

La passerelle de périphérie IG502 fournit un service réseau stable pour les sites IoT sans personnel avec :

- La double carte SIM bascule automatiquement vers le meilleur réseau.

- Détection de liens à plusieurs niveaux pour la récupération des défaillances.

- Technologie de chien de garde intégrée pour un fonctionnement ininterrompu.

Capacités avancées d'informatique en périphérie (Edge Computing)

Doté d'un processeur ARM Cortex-A8 (600 MHz), d'une mémoire vive de 512 Mo et d'une carte eMMC de 8 Go, l'IG502 assure un traitement intelligent des données, une optimisation en temps réel et des analyses intelligentes pour les appareils sur site.

Produits

Accédez à distance à vos machines sur site, n'importe où et n'importe quand.