Solution de télésurveillance pour usine numérique

Les usines numériques prospèrent grâce à la visualisation en temps réel, à la maintenance prédictive et à la prise de décision basée sur les données pour des opérations efficaces. Les solutions d'InHand, dotées d'une connectivité à haut débit, d'une compatibilité avec les protocoles industriels et d'une prise en charge de Docker, permettent un déploiement transparent et une gestion rationalisée.

Contexte

Dans le paysage industriel actuel, qui évolue rapidement, il est essentiel d'améliorer l'efficacité de la production, de réduire les coûts et d'assurer une gestion opérationnelle intelligente. Les solutions basées sur l'IoT pour la gestion à distance des usines numériques sont devenues essentielles, offrant aux entreprises des moyens innovants de rationaliser les opérations et de rester compétitives.

Exigences du client

Visualisation en temps réel et télégestion

Permet la surveillance en temps réel et la gestion à distance des équipements d'usine et des lignes de production automatisées. Accédez à l'état de l'équipement, aux mesures de production et aux indicateurs clés de performance à tout moment et en tout lieu pour prendre des décisions et procéder à des ajustements opérationnels en temps voulu.

Alerte aux pannes et maintenance prédictive

Fournir des capacités d'alerte pour identifier rapidement les dysfonctionnements, les anomalies et les problèmes potentiels. Mettre en œuvre des mesures de maintenance prédictive et préventive afin de minimiser les temps d'arrêt, de réduire les coûts de réparation et d'améliorer la fiabilité et la productivité des équipements.

Prise de décision et optimisation basées sur les données

Enregistrez et analysez les données opérationnelles des équipements de l'usine. Fournir des fonctions d'interrogation et d'exportation des données pour soutenir des décisions éclairées, optimiser l'utilisation des ressources et améliorer la gestion intelligente des usines numériques.

Solution

La solution de surveillance à distance d'InHand pour les usines numériques favorise une transformation IoT transparente, une maintenance rentable et une productivité accrue.

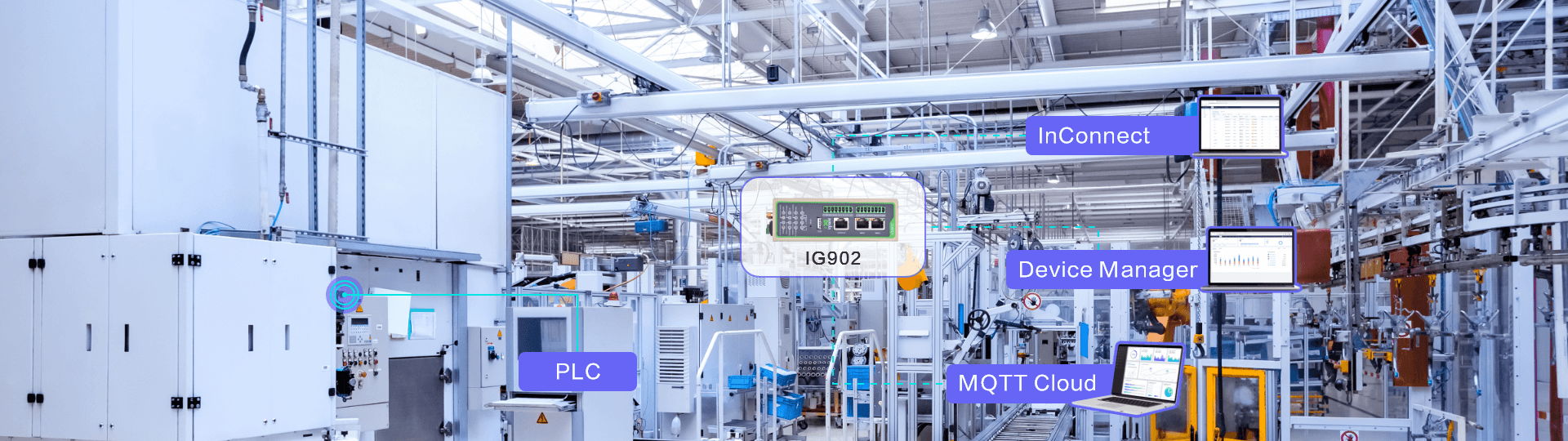

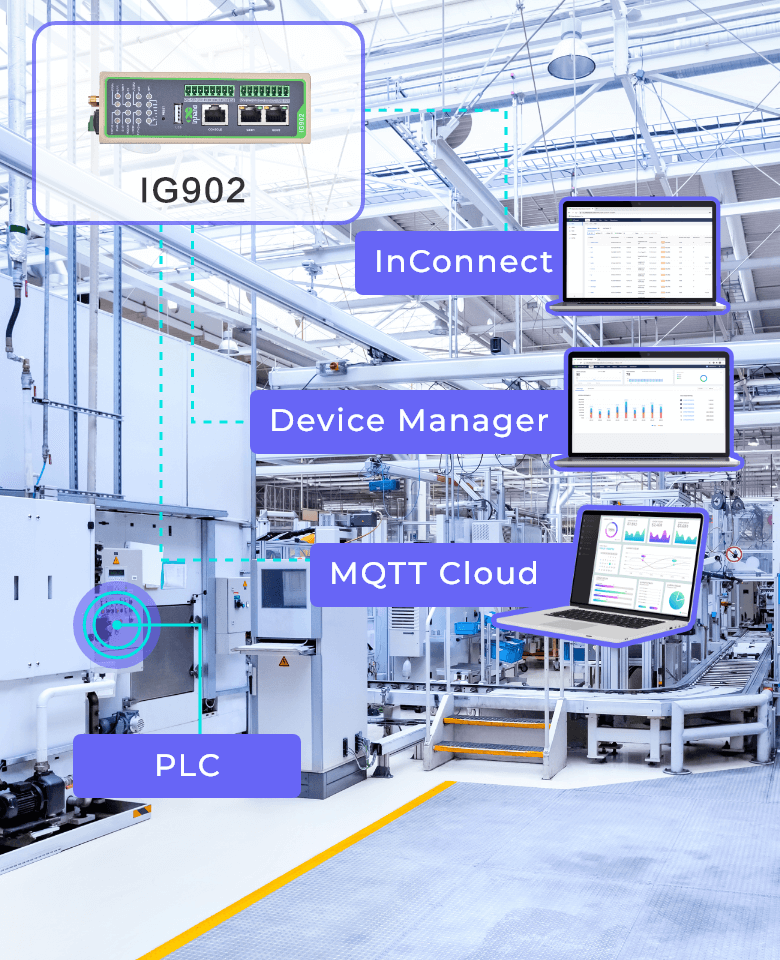

La solution comprend des automates de terrain, la passerelle IG902 edge computing gateway et une plateforme cloud IoT. La passerelle IG902 collecte les données en temps réel des automates, les filtre et les transmet en toute sécurité sur les réseaux 4G à l'aide de protocoles propriétaires à la plateforme de gestion à distance pour analyse.

Avec le service d'accès à distance InConnect, le personnel de maintenance peut configurer, déboguer et mettre à niveau les automates sur site à distance. La plate-forme DeviceManager permet une gestion unifiée des appareils, une maintenance à distance et une surveillance en temps réel, optimisant ainsi l'efficacité opérationnelle et prolongeant la durée de vie des équipements de l'usine grâce à la maintenance prédictive.

Capacités

Connectivité à haut débit, sécurisée et fiable pour un fonctionnement continu

Avec des options LTE, Wi-Fi et câblées, ainsi que des technologies de redondance de liaison, la passerelle IG902 IoT edge gateway garantit une transmission réseau ininterrompue, ce qui permet de maintenir les appareils en ligne.

Intégration transparente avec les protocoles industriels et les nuages

La passerelle IG902 prend en charge Modbus TCP/RTU, EtherNet/IP, ISO on TCP, OPC UA, etc., ce qui facilite la transmission des données vers le cloud pour la surveillance à distance et la maintenance préventive, réduisant ainsi les coûts d'exploitation.

Programmation Python pour la personnalisation

Dotée d'une plateforme de développement embarquée prenant en charge Python, la passerelle industrielle IoT IG902 permet aux développeurs de mettre en œuvre une logique commerciale spécifique et des solutions sur mesure.

Développement efficace avec Docker

La prise en charge de Docker permet de déployer des applications flexibles et évolutives, de réduire la consommation de ressources et de simplifier la configuration de l'environnement.

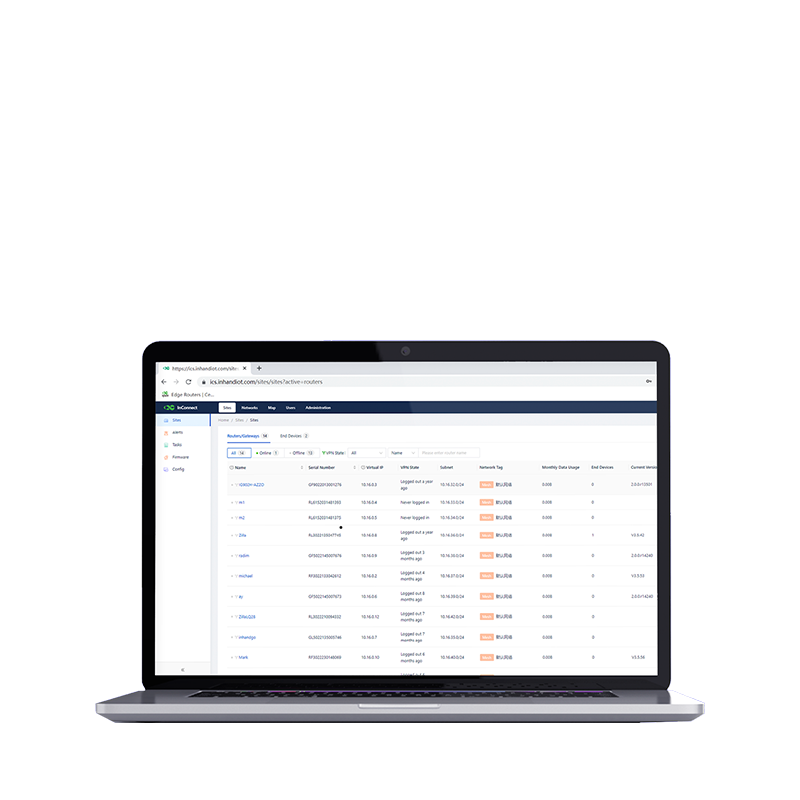

Télémaintenance avec InConnect

Le service d'accès à distance InConnect fournit des tunnels VPN sécurisés pour le débogage, les mises à jour et les ajustements de paramètres à distance de l'automate, garantissant des réponses rapides aux problèmes d'équipement.

Gestion simplifiée pour les déploiements à grande échelle

La passerelle IG902 prend en charge la configuration de l'interface web pour une mise en place rapide. Gestionnaire de périphériques centralise la gestion des appareils, ce qui permet de surveiller la passerelle en temps réel, à tout moment et en tout lieu.

Produits

Accédez à distance à vos machines sur site, n'importe où et n'importe quand.